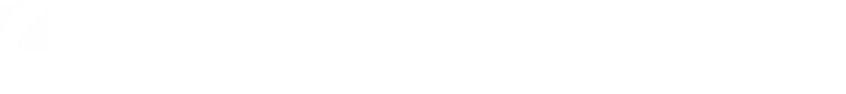

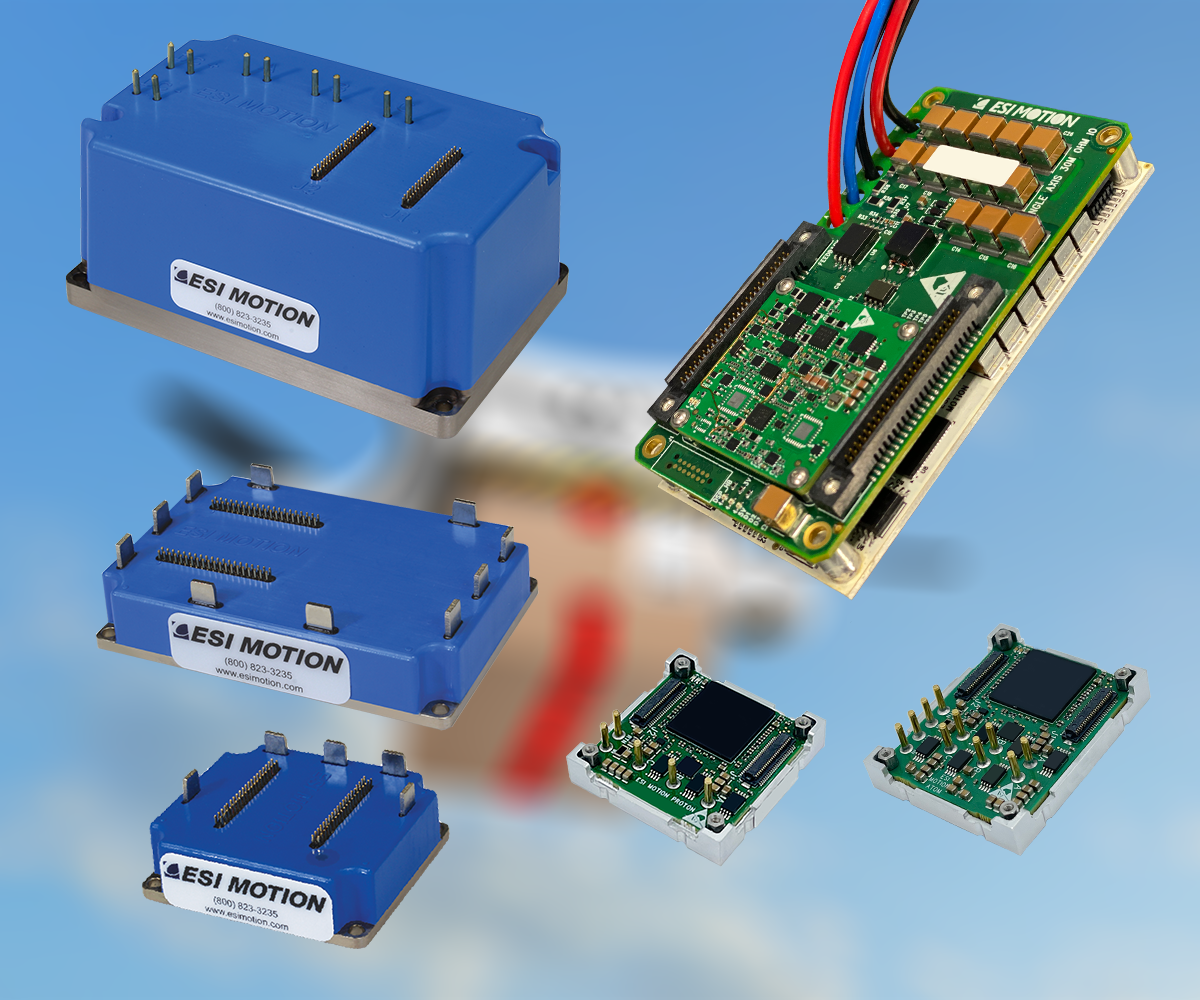

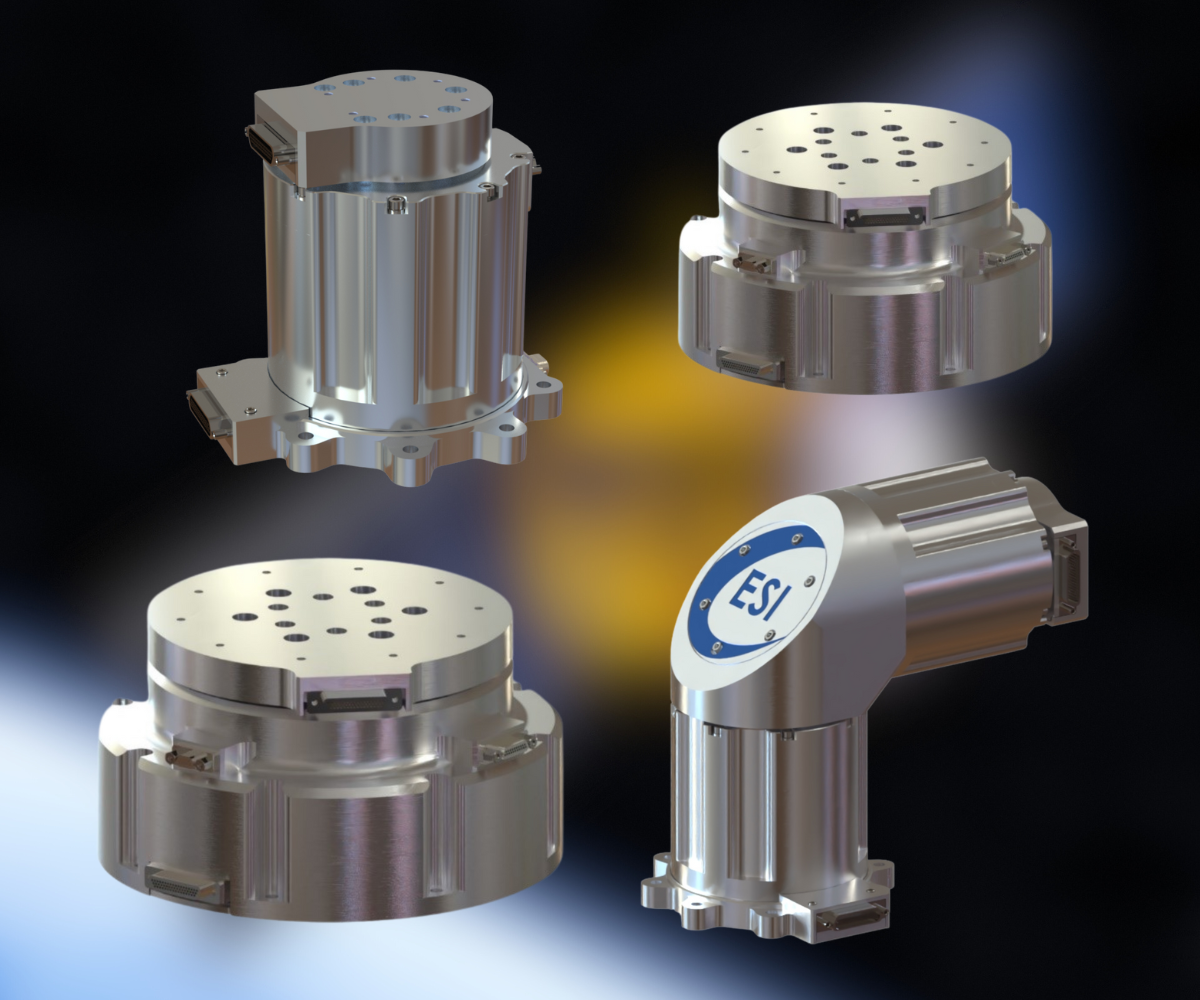

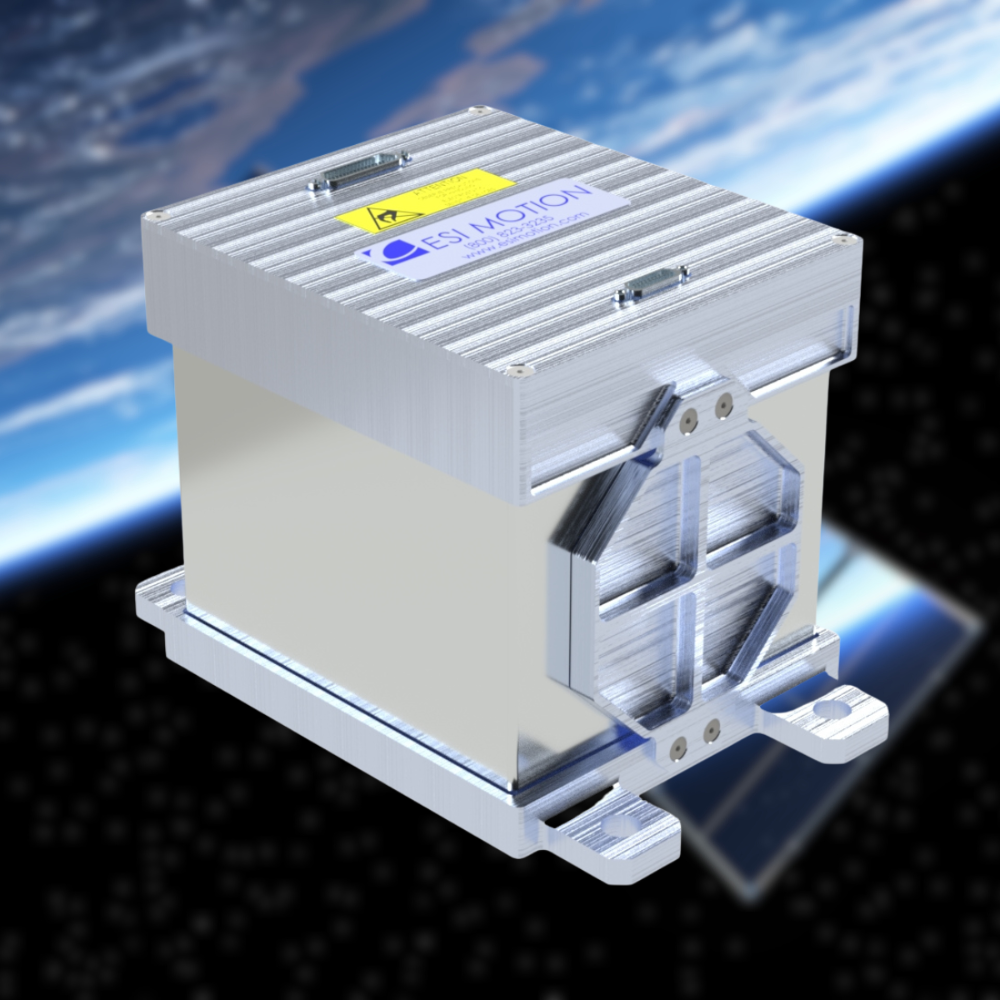

At ESI Motion, we are proud leaders in the motor control industry. Our ruggedized, high-power servo drives and servo drive modules are reinforced to provide world-class performance in the most extreme operating environments, allowing for precision and power anywhere from the bottom of the ocean to the vacuum of space. We adhere to the strictest standards in quality control and customer service, and our products are trusted by the largest governments and corporations in the world for mission-critical applications. No servo drive is complete without a motor, and many engineers or operators of motor control systems may wonder if it’s problematic to run a DC motor below its nominal voltage. To answer this question, we must first understand a few key variables about DC motors.

What Is Nominal Voltage?

There are a few key variables to keep in mind when evaluating a DC motor to understand its performance: nominal voltage, stall torque, and no-load speed. These terms are defined as follows:

Nominal Voltage:The manufacturer-recommended voltage at which to operate the motor. Most DC motors come with a recommended range of voltages, but the nominal voltage is the voltage that the motor was built to operate at.

No-Load Speed:This is the speed the motor will turn when run at nominal voltage with no load (i.e. no resistance to rotation).

Stall Torque:The maximum amount of torque the motor will produce at nominal voltage, named so because it only occurs when the motor is stalled and not turning.

At nominal voltage, the no-load speed and stall torque of a DC motor exist at opposite ends of a continuum. On one end, the motor runs without a load and thus spins as quickly as possible: its no-load speed. At the other, the motor does not spin and produces the maximum possible amount of torque on the load: its stall torque.

What Happens When Running a DC Motor at Lower Than Nominal Voltage?

The simple answer to this question is that a DC motor run below its nominal voltage will be capable of a slower no-load speed and a lower stall torque. Running a DC motor below nominal voltage generally will not cause any problems with the motor. If anything, the motor will last longer because it won’t be subject to the same level of stress (from heat, friction, and general wear) as it is when running at the full nominal voltage.

The same thinking can be applied to a fully ruggedized servo drive. Our fully ruggedized servo drives adhere to military-grade standards and can operate in the harshest of environments, withstanding extreme temperatures, extreme pressures, high vibration, and corrosive chemicals. However, running the servo drive at room temperature will not cause a problem. The servo drive will operate just as well. Similarly, a DC motor run below nominal voltage will turn slower and produce less heat during operation, but that in no way damages the motor.

Contact Your Rugged Servo Drive Experts

Running a DC motor below its nominal voltage may make sense in a variety of engineering situations and applications, but for ideal performance in a motor control system, nothing beats a high-performance servo drive. At ESI Motion, we’ve been supplying industries ranging from space exploration to deep sea drilling with powerful, rugged servo drives built to last in any environment. Contact us today to find out more about our products and how we can help your next motor control system exceed your expectations.