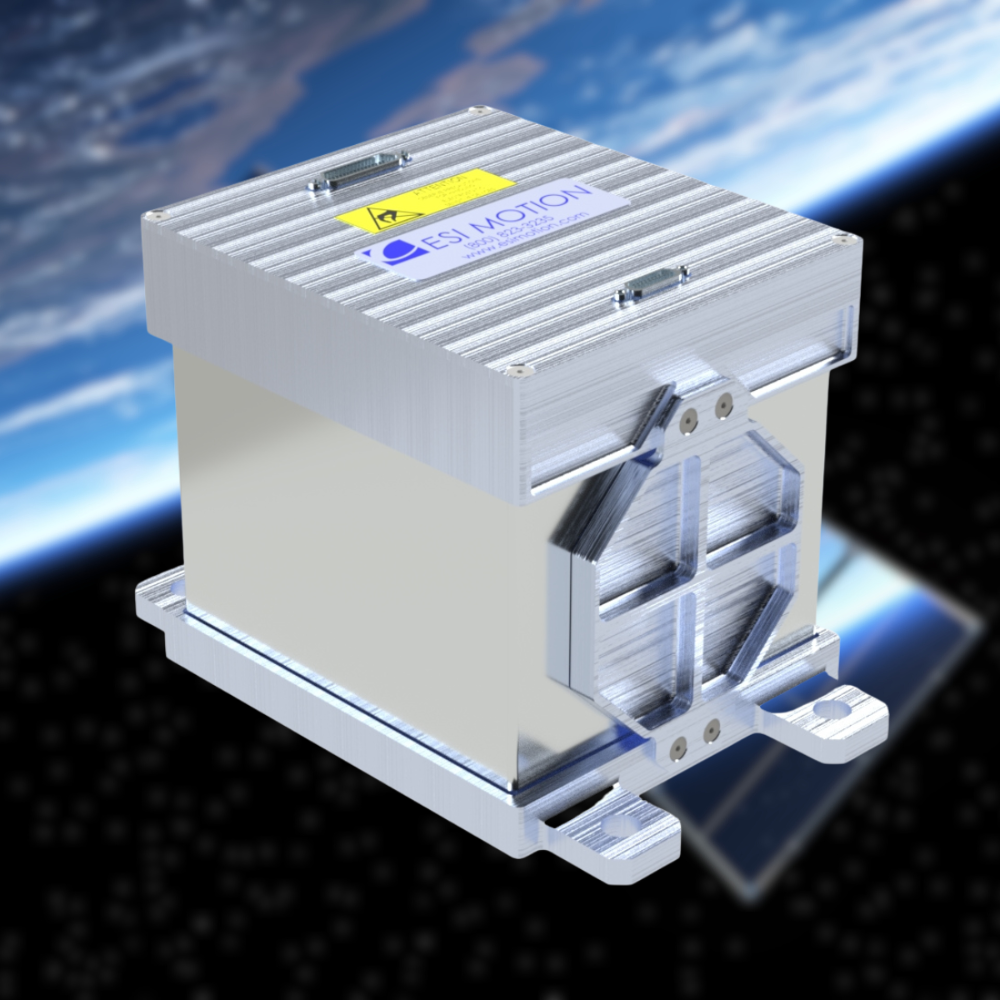

ESI's Manufacturing and Support Commitment

ESI Motion is known for our ruggedized servo controllers, but we are about a lot more than just hardware. The entire ESI team is committed to delivering unmatched service and support to our clients. Employees collaborate closely with suppliers, partners and clients to create open communication channels and foster mutually beneficial relationships. Our policy is “The Management of ESI Motion and our employees are committed to meeting the requirements of our customers and continually improving our processes to provide quality products.”

Our quality assurance program is rooted in the Six Sigma and Total Quality Management philosophies. This foundation, along with a dedicated team, promotes the following:

We strive to reach zero defects with every solution.

Quality design is integrated into every company process.

Understanding that simple designs are usually the best solutions.

Driving continuous improvement with every decision and change.

AS9100D Certification

ESI Motion follows strict AS9100D quality management and documentation processes, six sigma process improvement methodology and industry standard project management practices.

These practices along with ESI Motion’s highly specialized technology allow us to consistently deliver on-time, high-quality products that exceed client expectations.

The AS9100D certification is a standardized quality management system for the defense and aerospace industries. ESI Motion is proud to be recognized in this elite class of manufacturers and companies and strives to exceed even the expectations of the certification program with every relationship.

An AS9100D certification indicates that ESI Motion has demonstrated the ability to consistently provide a product that meets or exceeds the requirements set forth by the client and any related industry or regulatory standard. It also demands that ESI improve customer satisfaction by continually using feedback to improve internal processes.

For ESI Motion, a great customer experience and a quality product are paramount to success. We work closely with Perry Johnson Registrars to maintain and improve all aspects of our business with periodic audits and comprehensive reporting. While not an industry requirement, this helps us ensure we are providing excellent products and services always. Visit Perry Johnson Registrars to learn more.

Compliance with Standards

Functional Safety

| Safe Torque Off (STO) Safety Standard |

Item |

|---|---|

| The related standards below apply to the performance of the servo drives as stated in the environmental conditions | |

| IEC 61800-5-2:2007 SIL 3 | Adjustable speed electrical power drive systems – Safety requirements – Functional |

| EN ISO 13849-1:2008 Cat 3, PL e | 3850W (80 VDC Bus, Motor CuaSafety of machinery — Safety-related parts of control systems.rrent 50 Amps peak-of-sin) |

| EN 61508-1:2010 SIL 3 | Functional safety of electrical/electronic/programmable electronic safety-related systems |

| EN 61508-2:2010 SIL 3 | Functional safety of electrical/electronic/programmable electronic safety-related systems |

| EN 61508-3:2010 SIL 3 | Functional safety of electrical/electronic/programmable electronic safety-related systems |

Safety

| Specification | Details |

|---|---|

| The related standards below apply to the performance of the servo drives as stated in the environmental conditions | |

| Approved IEC/EN 61800-5-1 | Adjustable speed electrical power drive systems Safety requirements – Electrical, thermal and energy |

| Recognized UL 61800-5-1 | Adjustable speed electrical power drive systems Safety requirements – Electrical, thermal and energy |

| Recognized CSA C22.2 NO. 14-13 Or Recognized CSA C22.2 NO. 274-13 |

Industrial Control Equipment Adjustable drive speeds |

Environmental

| Specification | Details |

|---|---|

| Approved IEC60068-2-78 | Environmental testing – Damp heat, steady state |

| Approved IEC60068-2-6 | Environmental testing –Vibration (sinusoidal) |

| Approved IEC60068-2-2 | Environmental testing – Dry heat |

| Approved IEC60068-2-27 | Basic environmental testing procedures – Shock |

EMC

| Specification | Details |

|---|---|

| Approved IEC/EN 61800-3 | Adjustable speed electrical power drive systems |

| In compliance with EN 55011 Class A with EN 61000-6-2: Immunity for industrial environment, according to: IEC 61000-4-2 / criteria B IEC 61000-4-3 / criteria A IEC 61000-4-4 / criteria B IEC 61000-4-5 / criteria B IEC 61000-4-6 / criteria A IEC 61000-4-8 / criteria A IEC 61000-4-11 / criteria B/C |

Electromagnetic compatibility (EMC) |

| Approved IEC 61326-3-1 | Electrical equipment for measurement, control and laboratory use. Standard required for STO. |

EC Declaration of Conformity

| Directive | |

|---|---|

| Low Voltage Directive, 2014/35/EU (LVD) | |

| Electromagnetic Compatibility Directive 2014/30/EU (EMC) | |

| Machinery Directive 2006/42/EC |

| Standard | Details |

|---|---|

| IEC 61800-5-2:2007 | Adjustable speed electrical power drive systems – Safety requirements – Functional |

| EN ISO 13849-1:2015 | Safety of machinery — Safety-related parts of control systems. |

| EN 61508-1:2010 | Functional safety of electrical/electronic/programmable electronic safety-related systems |

| IEC/EN 61800-5-1:2007 | Adjustable speed electrical power drive systems Safety requirements – Electrical, thermal and energy |

| EN 61800-3:2004 + A1:2012 |

EMC Adjustable speed electrical power drive systems |

Other Compliant Standards

| Quality Assurance | |

|---|---|

| ISO 45001:2018 ISO 9001:2015 ISO 14001:2015 |

Occupational Health and safety Management System Quality Management Environmental Management System |

| Design | |

| IPC-D-275 IPC-SM-782 IPC-CM-770 |

Printed wiring for electronic equipment (clearance, creepage, spacing, conductors sizing, etc.) |

| Reliability | |

| MIL-HDBK- 217F | Reliability prediction of electronic equipment (rating, de-rating, stress, etc.) |

| Workmanship | |

| In compliance with IPC-A-610, level 3 | Acceptability of electronic assemblies |

| In compliance with IPC-A-620, level 3 | Requirements and Acceptance for Cable and Wire Harness Assemblies |

| PCB | |

| In compliance with IPC-A-600, level 3 | Acceptability of printed circuit boards |

| Packing | |

| In compliance with EN 100015 | Protection of electrostatic sensitive devices |

| Environmental | |

| In compliance with WEEE Directive 2012/19/EC | Waste Electrical and Electronic Equipment regulations (WEEE) |

| In compliance with ROHS Directives 2011/65/EU and 2015/863 |

Restrictions on Application of Hazardous Substances in Electric and Electronic Equipment (RoHS) |

Why EtherCAT?

- EtherCAT is leading as far as unmatched performance.

- The strength of EtherCAT synchronization techniques allows it to be compatible with high-demanding and simpler applications.

- Combined with the correct implementation of both the network protocol and a proper device profile, true distributed motion controlcan now be achieved.

EtherCAT and Your Machine

There is a great difference between a product that uses its own interpretation of a communication protocol and one that meets a universally accepted standard that provides product engineers with huge advantages such as:

- Fast and simple integration with any other compliance product.

- Proper and reliable operation of the network in terms of efficiency, speed, bus load, etc.

- Efficient and fast communication transportation.

- High levels of synchronization and coordination of the nodes.

- Superior cycling, synchronization for optimal multi-axis applications.

- An “open” network for adding, omitting, replacing (including vendors), upgrading nodes of any compliant product.

- Compatibility with future compliant products and solutions.

Compliant to:

Quality Service Begins With Great People

Maintaining this level of service excellence is fueled by the passion of our entire group. ESI Motion employs team-minded professionals with experience in quality systems and standard industry practices. ESI’s operations management are fully certified in Project Management (PMP) and Six Sigma and have years of experience implementing strict quality processes and process improvements.

ESI uses a combination of internal Standard Operating Procedures (SOPs) and industry certifications to maintain quality control. Our internal SOPs give us a high degree of control over the systems and processes that affect our products.