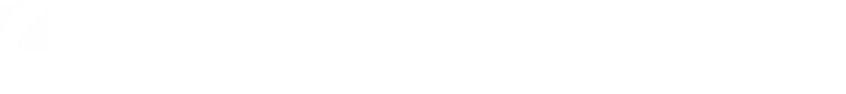

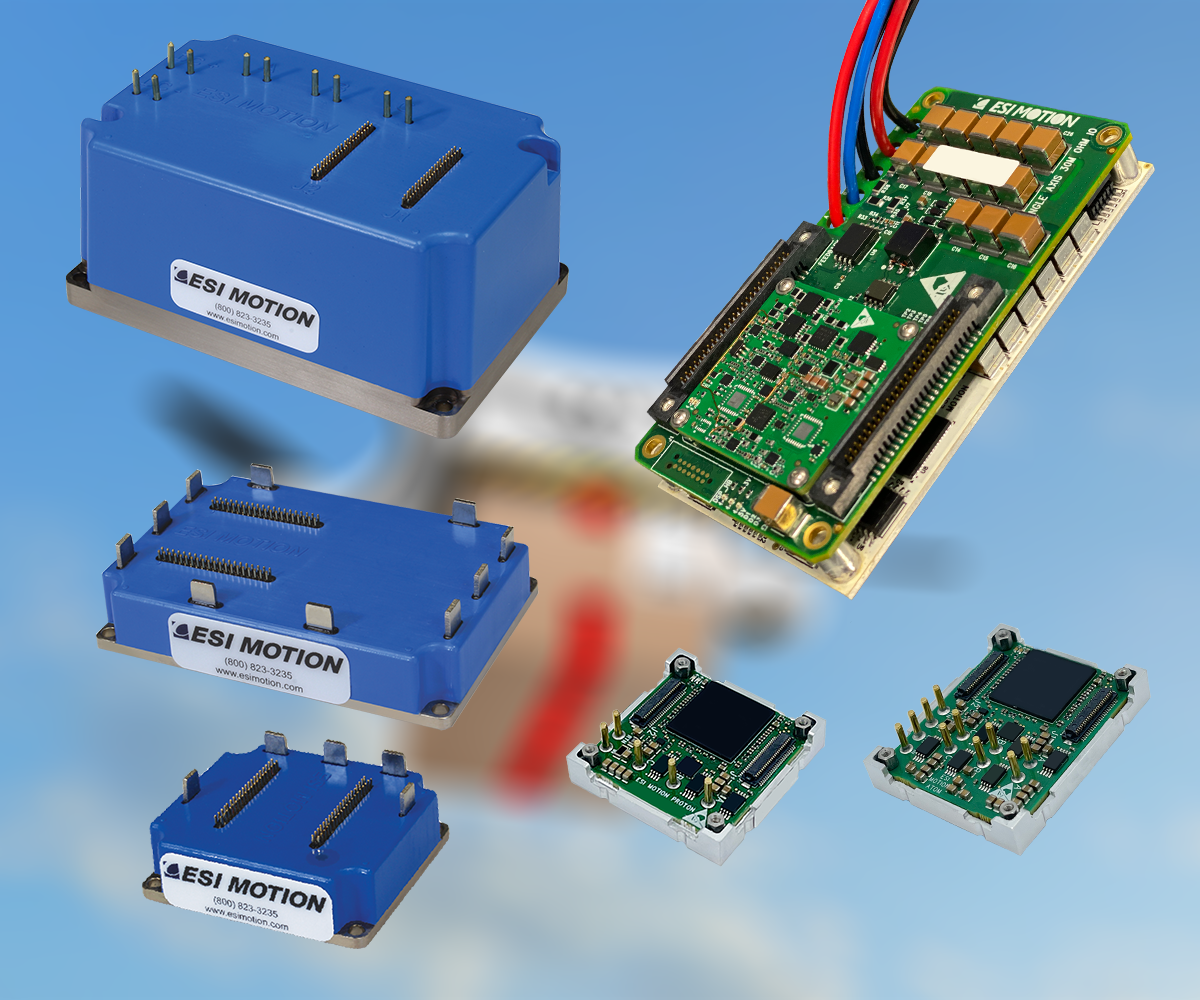

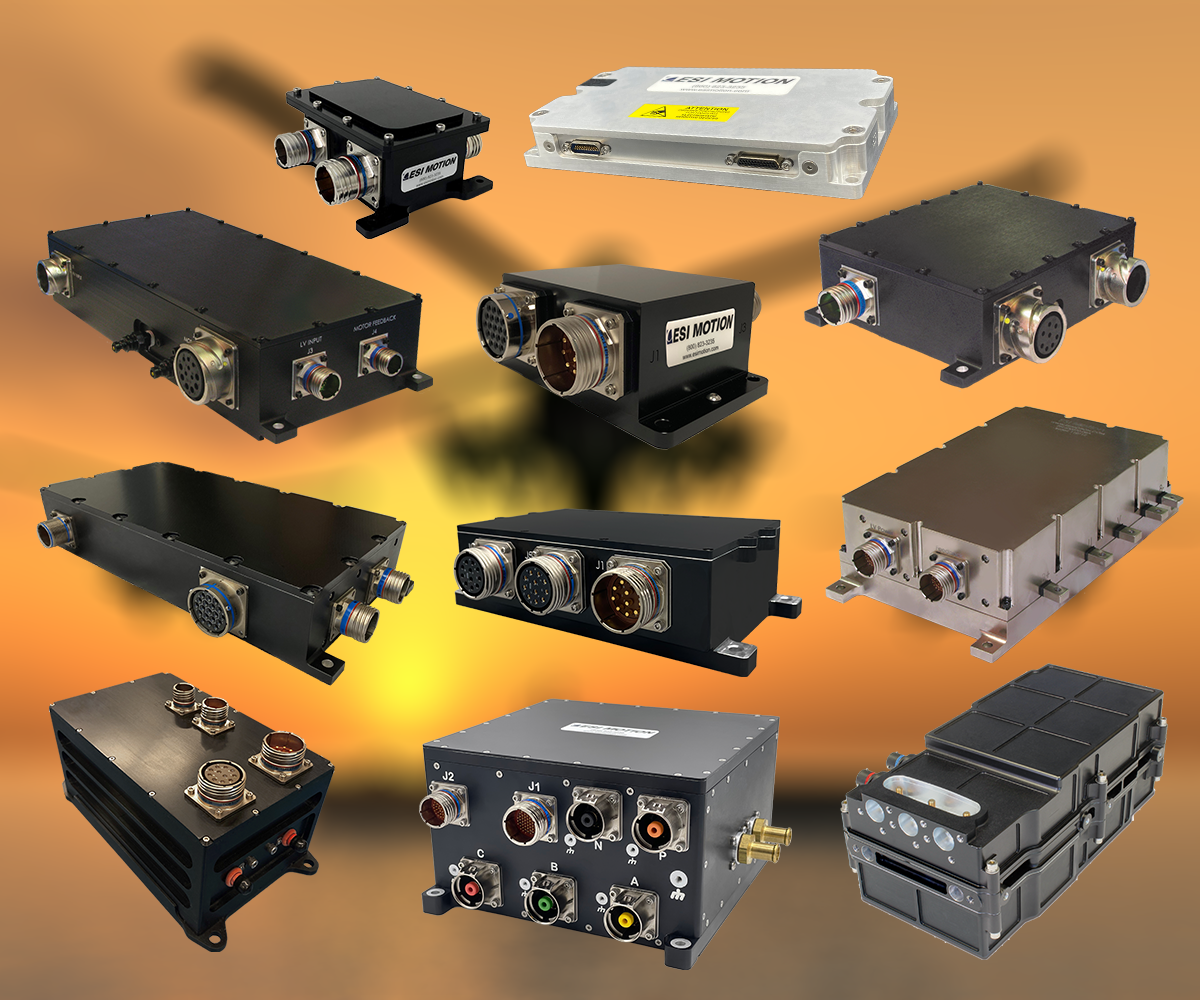

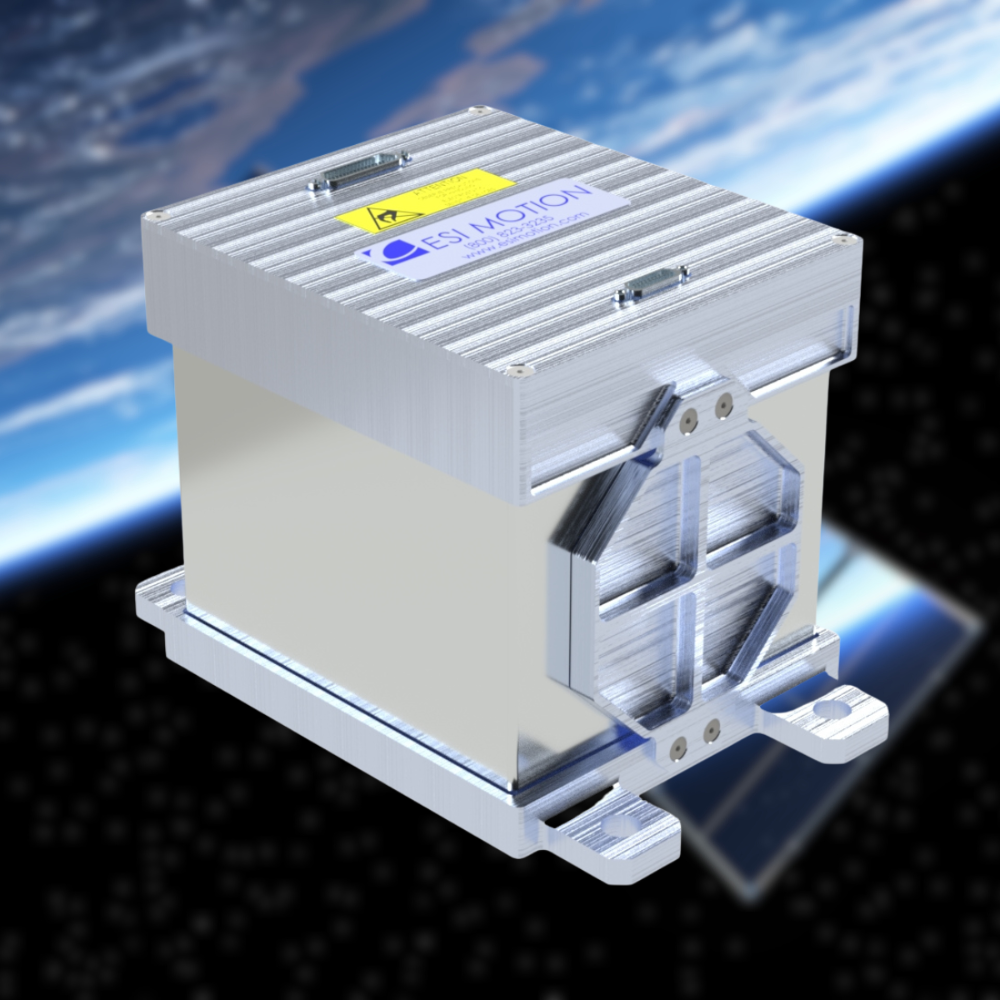

At ESI Motion, we’re proud to produce some of the most powerful, reliable, and durable servo drives on the market today. Our mission is to “do it right the first time,” and we adhere to a rigorous standard of quality for every product we produce. Our servo drives are trusted by some of the largest governments and companies in the world and can withstand the harshest operating environments, playing mission-critical roles in industries ranging from deep-sea drilling to space exploration. However, even the most powerful servo drive can’t function without a motor – and, at a basic level, how do motors work?

How DC Motors Work

The DC Motor is one of the most fundamental, widely-used machines in the world. First invented by British scientist William Sturgeon in 1832, DC motors were critical in bringing about the industrial revolution and have played a central role in virtually all engineering applications since. Today, DC motors lie at the heart of everything from remote control cars to M1A1 Abrams tanks, and the underlying technology is still much the same as it was in Sturgeon’s day.

Fundamentally, motors work thanks to magnetism. Imagine taking a large copper wire and wrapping it into a loop, then laying that between the poles of a big horseshoe magnet. Now, imagine connecting the ends of the wire to the two terminals of a battery. This connection will form a circuit, causing electricity to flow through the copper wire – but electricity isn’t the only thing flowing.

Any flow of electricity generates both an electric field and a magnetic field. This means that connecting the copper wire to a battery causes the wire to have a magnetic field. That magnetic field will then interact with the magnetic field of the horseshoe magnet, causing the copper wire to jump and orient itself to the field of the horseshoe magnet. This jump is caused by the same phenomenon that allows motors to work.

A motor takes this “jump” and refines it. Instead of moving freely, the wire is attached to a central shaft and surrounded by a permanent magnet. When current flows through the wire it tries to “jump,” but because it’s fixed to the shaft, it can’t. Instead, the shaft turns, creating a motor.

Astute readers may notice that in our first example, the copper wire stopped once it oriented itself to the magnet. So why don’t motors do the same? Actually, without intervention, a motor would naturally rotate 180º and back again. There are two ways to solve this problem and create rotation. One is to change the direction of the electric field each time the motor reaches its turning point. This is called alternating current (AC), and it’s the type of electricity that comes out of a wall socket. The second is to use a device called a commutator to change the direction of the current inside the motor. A DC motor is simply a regular electric motor with a commutator attached, allowing it to run on direct current (DC).

Contact ESI Motion Today

Electric motors lie at the heart of virtually all motion control – and ESI Motion’s high-performance servo drives make them even more effective. Whether it’s the flaps of a fighter jet or the wheels on a Mars rover, our rugged servo drives are designed for maximum performance in difficult operating environments. If you’re interested in learning more about ESI Motion or want to discuss a project, feel free to reach out to us at our contact page. No matter what you’re looking for, we’ll work with you to create a solution that exceeds your expectations and delivers world-class performance in the toughest applications in the world. We look forward to hearing from you.