Stepper motors are a type of electric motor that converts electrical pulses into precise mechanical movements. They are widely used in various applications where precise control of position or rotation is required, such as 3D printers, CNC (Computer Numerical Control) machines, robotics, and more. Stepper motors work on the principle of electromagnetism and use a unique design to achieve their characteristic step-by-step movement.

Here's how stepper motors work:

1. Basic Components:

A stepper motor consists of several key components:- Rotor: The central rotating part of the motor, typically made of a permanent magnet or iron core.

- Stator: The stationary part of the motor, which contains coils of wire arranged in specific configurations.

- Driver: An electronic circuit or controller that sends electrical pulses to the motor to control its movement.

2. Coil Arrangement:

The coils in the stator are arranged in a specific pattern. The most common configurations are:- Bipolar: In this arrangement, there are two coils, and each coil has a center tap connection. The current can flow in both directions through each coil.

- Unipolar: In this arrangement, each coil has a center tap connection and a connection at each end. The current flows in only one direction through each coil.

3. Pulse Control:

To make the stepper motor move, you send a sequence of electrical pulses to the coils. The sequence and timing of these pulses determine the motor's rotation or position. Each pulse corresponds to a "step," which is the smallest unit of movement for the motor.4. Magnetic Interaction:

When current flows through a coil, it generates a magnetic field. The arrangement of the coils and the timing of the pulses cause the rotor to align itself with the magnetic field, trying to minimize the magnetic resistance. As a result, the rotor moves incrementally to align with the next coil.5. Step Modes:

Stepper motors can operate in various step modes, such as full step, half step, or microstepping. In full-step mode, the motor moves one full step for each pulse. In half-step mode, it moves half a step for each pulse, effectively doubling the resolution. Microstepping further subdivides each step into smaller increments, providing even finer control.6. Accuracy and Precision:

Stepper motors are known for their accuracy and precision, as they move in discrete, predictable steps. However, their maximum speed is limited compared to some other types of motors, and they may lose steps if overloaded.7. Feedback:

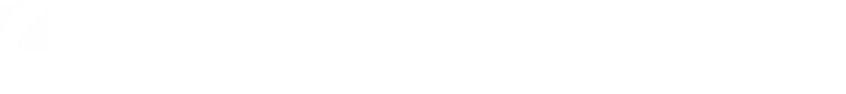

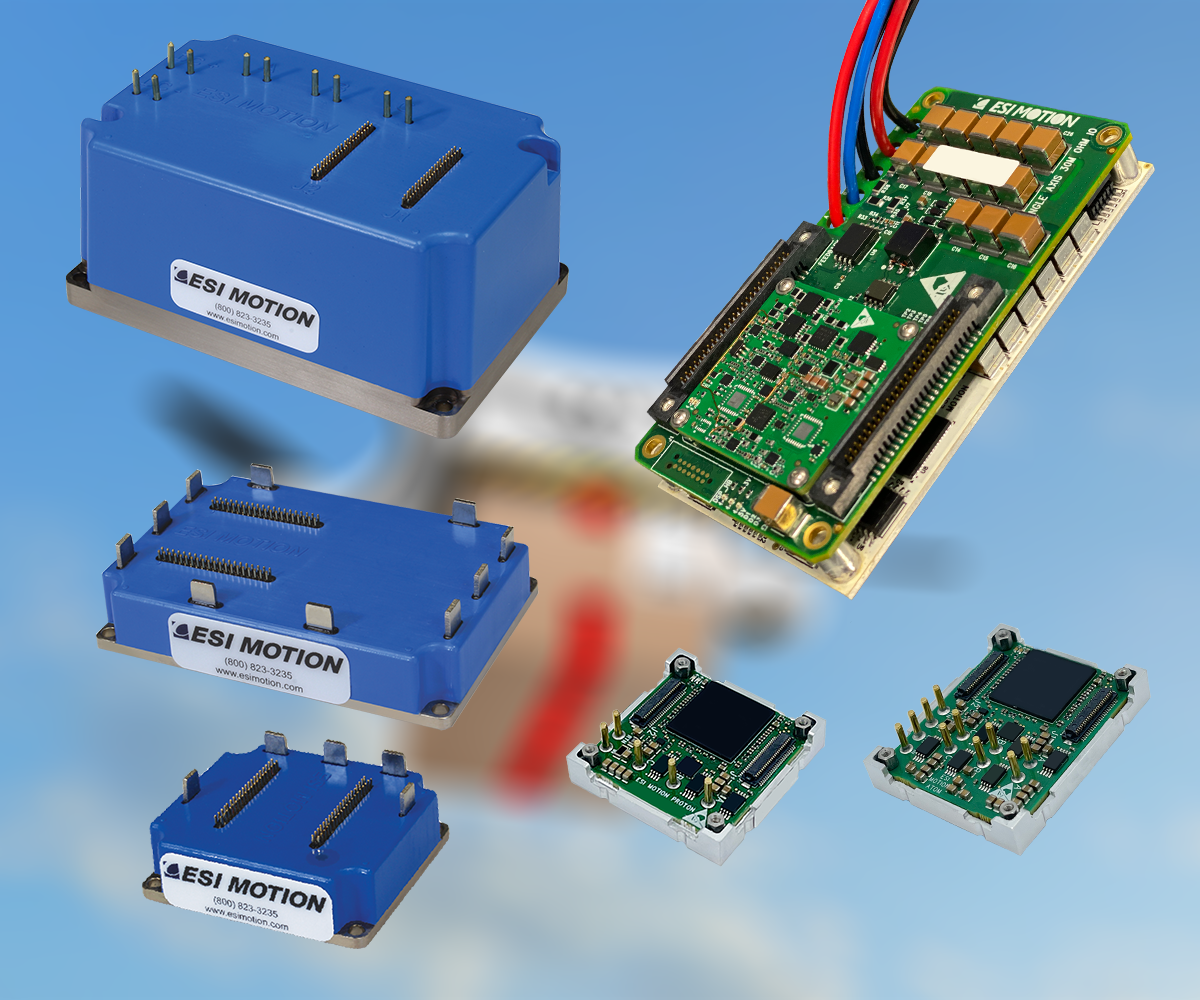

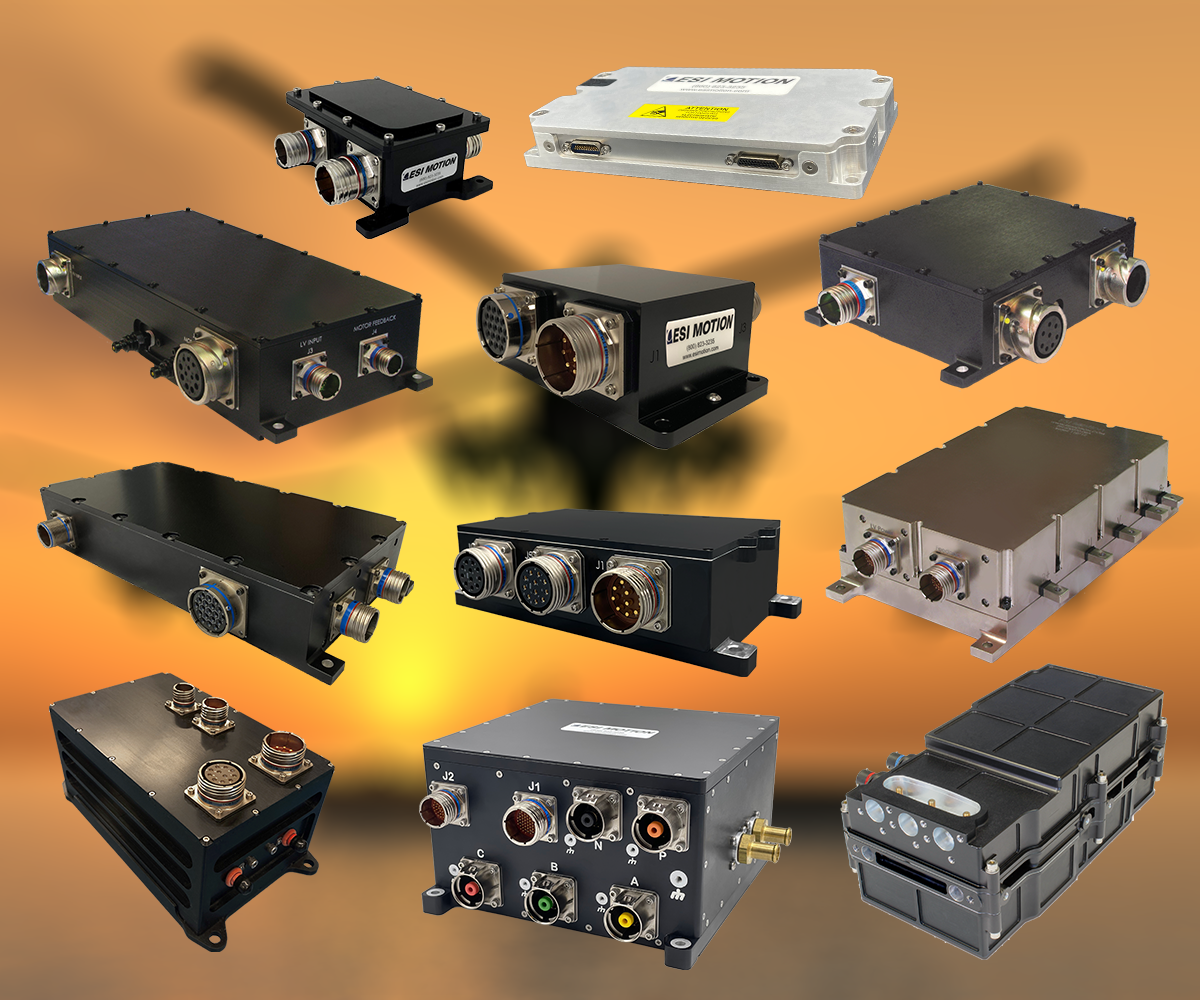

In some applications, stepper motors are combined with encoders or sensors to provide feedback and ensure precise positioning, especially in situations where missed steps must be corrected.With all this, stepper motors work by converting electrical pulses into mechanical movement through a combination of magnetic fields and precise coil arrangements. By controlling the timing and sequence of these pulses, you can achieve accurate and controlled rotation or linear movement. For Servo Drives, most are designed to work solely with a Servo Motor. However here at ESI Motion we have the experience and capability for Stepper Motors and Servo Drives to work together and achieve your mission goals.

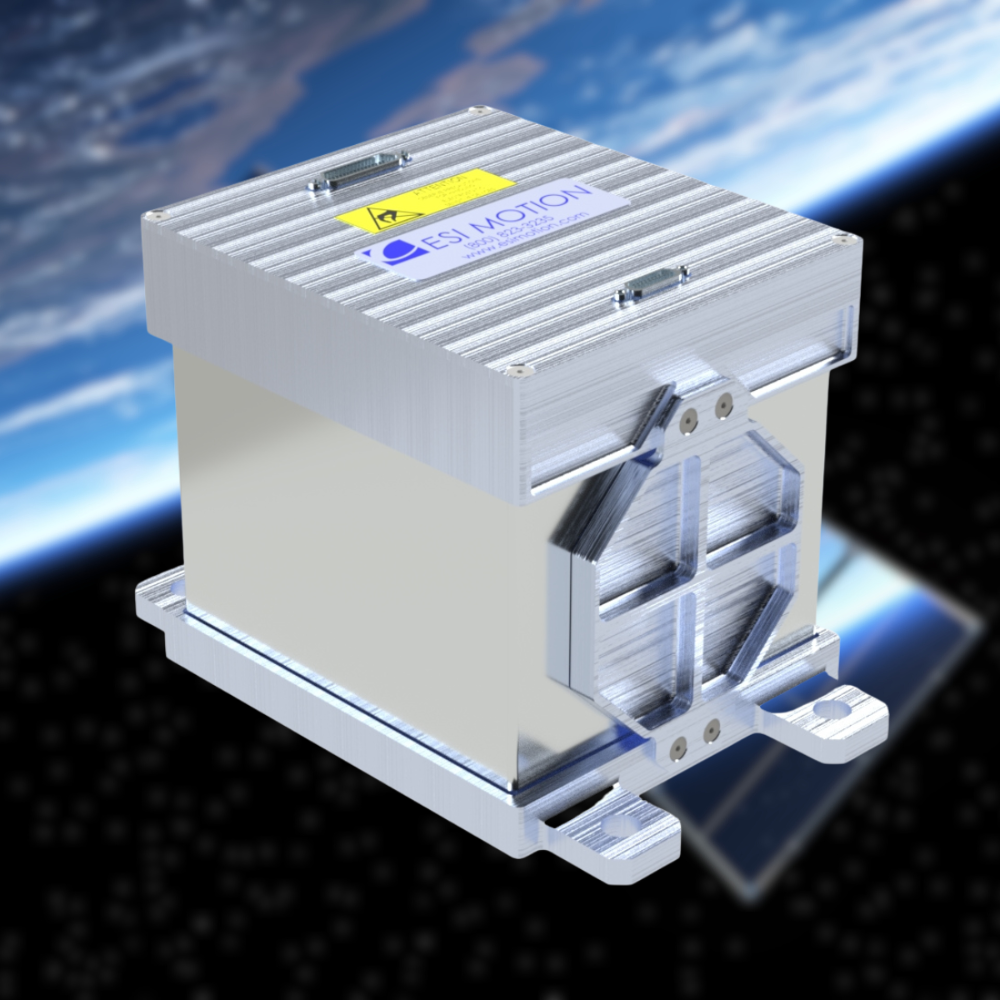

Both ESI Motion Servo Drives and Stepper Motors work to perform precise control of position or rotation while embracing harsh environments, including Space. You do not have to sacrifice quality and time in finding a solution that works with stepper motors. To learn more or have your questions answered, Contact Us Here.

Contact Us Today

As an industry leader, ESI Motion possesses the know-how, experience, and support to help you achieve your mission goals while ensuring optimal performance and longevity for your equipment.

Contact ESI Motion by calling +1.800.823.3235 or email us at sales@esimotion.com. We can help you find the right solution for your space system needs.

If you’ve got any questions, we’ve probably got them answered here on our FAQ. If you need any technical support, our team is here to help.

Click Here to see more of our solutions.

Check out our products and their capabilities here.