Rolling bearings are the great unsung heroes of engineering. They bear enormous loads, deliver consistent performance again and again, and they let us work the great magic of mechanical engineering, friction reduction. But as powerful as these components are, it takes the right tool to do the job well. When selecting a rolling bearing, there are three main things to keep in mind: available space, applied load, and rotational speed.

Available Space

We need say little on this, as it is one of the most familiar constraints in the whole of systems and machine design, if there is not enough space for your bearing within the machine, then it will not do you any good! Make sure the bore diameter of your bearing matches the necessary shaft diameter, and make sure cross-sectional dimensions of the bearing will fit the application.

Applied Load

Bearings will not work without some load, but each kind of bearing works best with a different load size. When you need high performance with a heavy load, lean towards roller bearings, but if you need your bearing to be nimble with little weight, look for a ball bearing.

Rotational Speed

Finally, it is critical to make sure that the operating rotational speed of your system is within your bearing’s permissible operating speed; in some systems, you can actually get the bearing to operate above its reference speed. You can do so by using small, specifically measured doses of lubricant to reduce friction or using circulating lubricant, cooling ribs, or air cooling to reduce heat. Also, you can sometimes get a bearing to operate above its reference speed. In general, though, want to make sure that the bearing’s speed rating matches your system requirements.

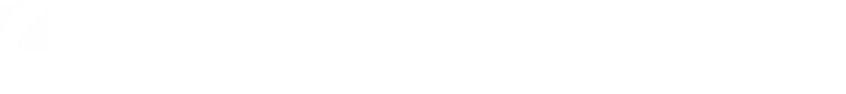

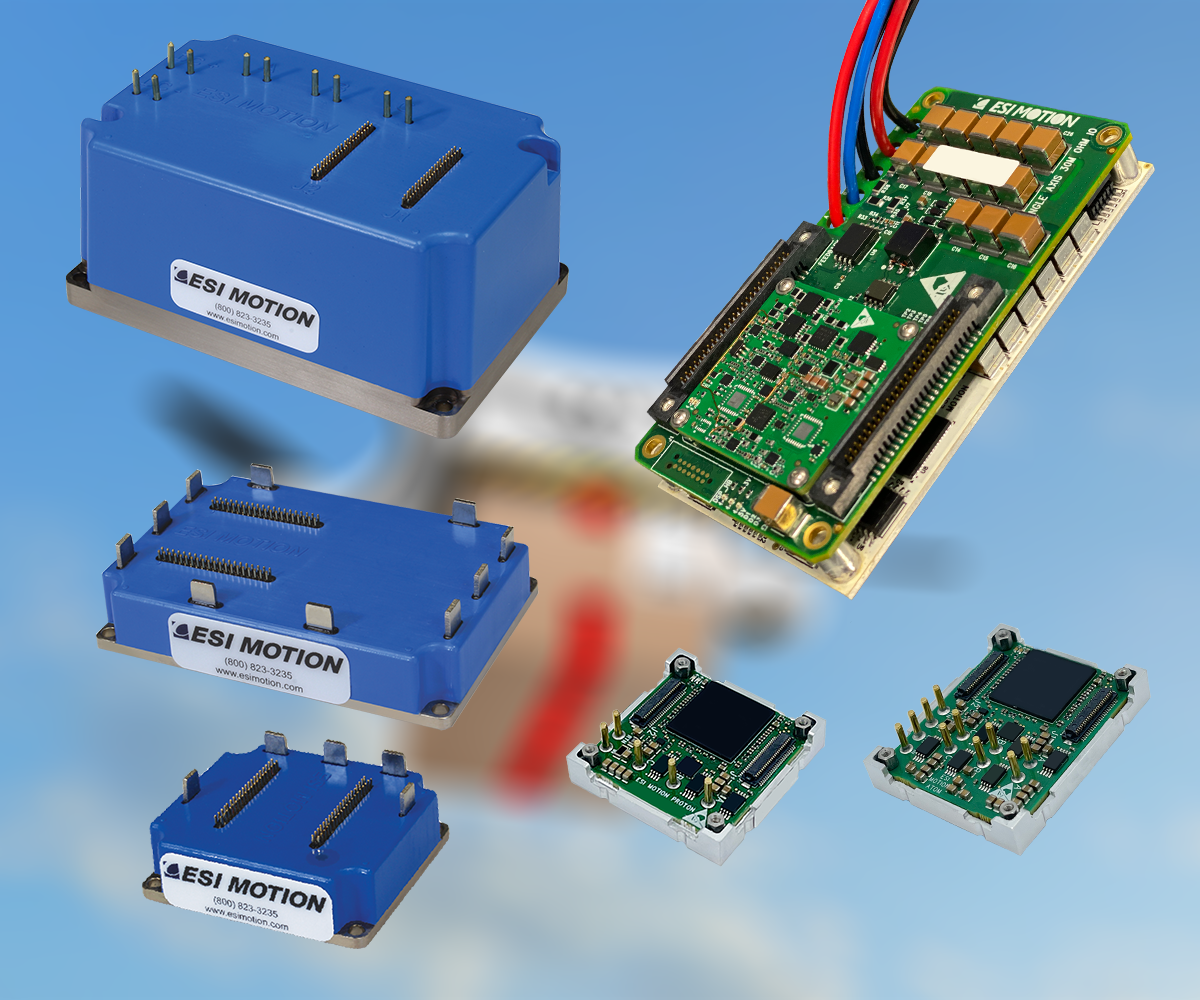

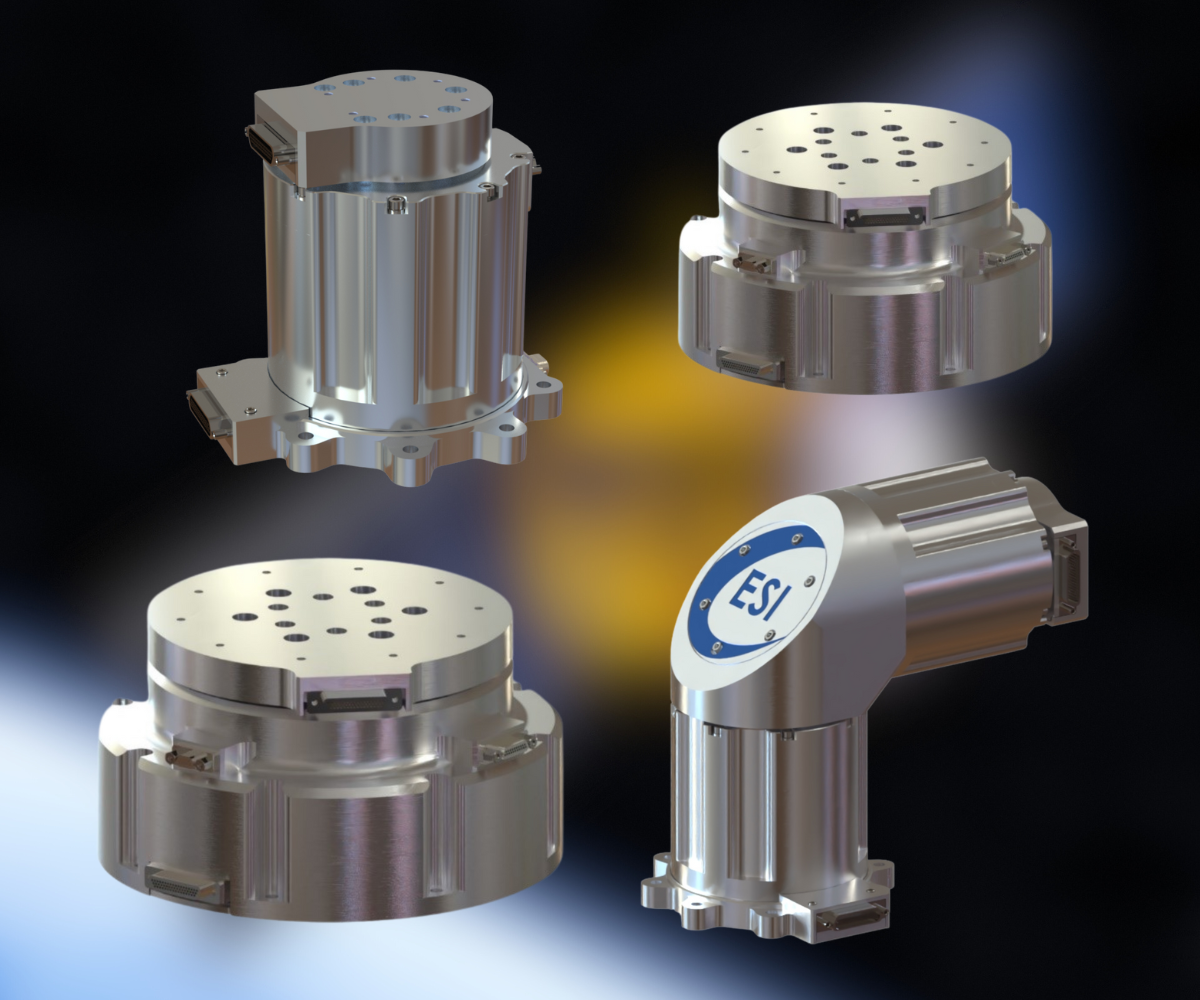

Contact Your Servo Drive Experts

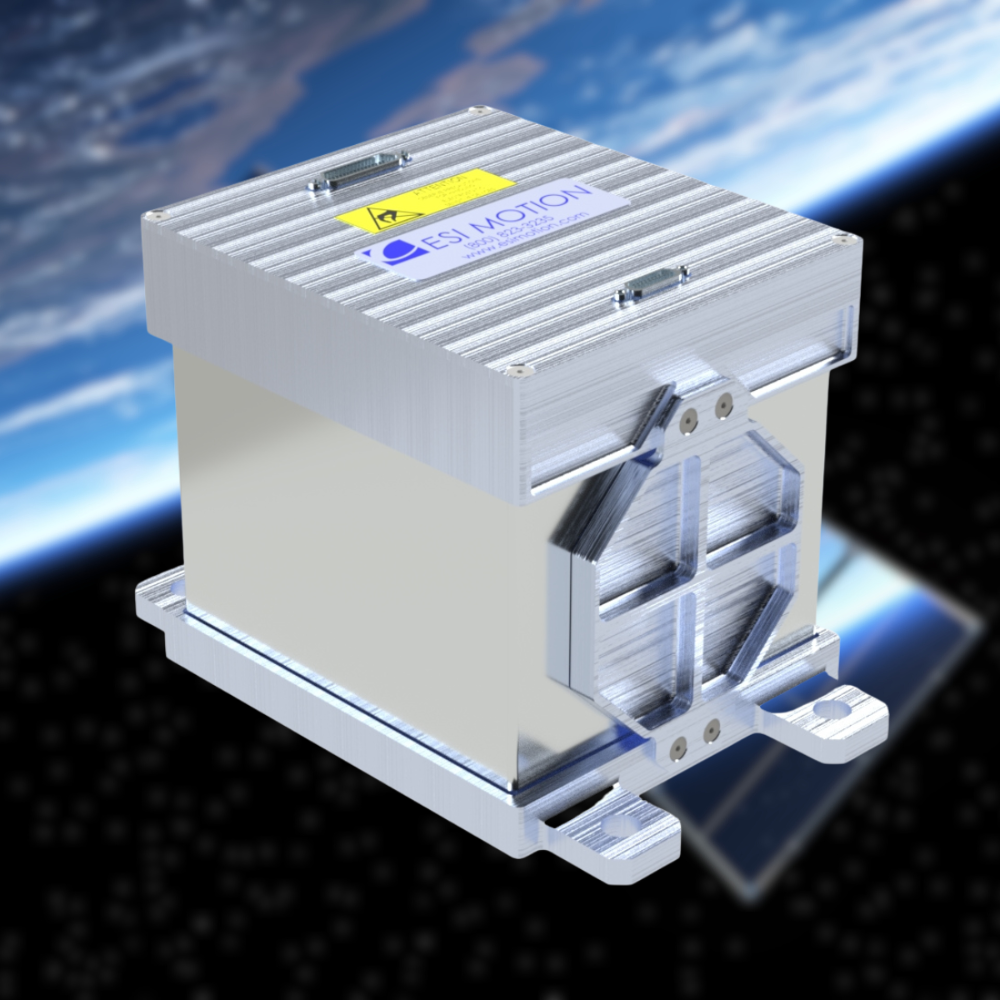

Once you have chosen all your bearings, you will need a servo drive that can help your system perform at its best, and that is where ESI Motion comes in. With a variety of durable, compact, and servo drives and modules that operate in the most extreme conditions on Earth, we can satisfy all of your motion control system needs. Feel free to reach out to us at 1.800.823.3235 to discuss your project requirements, and do not forget to check back to this blog for more tips on how to keep your motion systems working at maximum capacity.