Actuators are critical for making complex systems work, and to ensure effectiveness, choosing the right one for the application is paramount. While hydraulic actuators are great for the power they can exert and pneumatic actuators offer a quick, highly responsive form of control, electric actuators are widely versatile and easy to maintain because they don’t require oil. To choose the right electric actuator, you’ll want to consider a number of factors.

Motion Profile

First, you’ll want to consider what the actual required motion profile is. This will give you what you need in terms of velocity, force and travel distance. In addition, this will also help you determine the maximum stroke needed and what speeds you’ll want.

Load

You’ll also want to know load, which can mean understanding the inertial, frictional, gravitational and the external applied load. Keep in mind that to make these calculations, you’ll need to know the horizontal or vertical orientation of the actuator.

Duty Cycle

You’ll also want to understand the duty cycle, which is the ratio of time it’ll be operating versus resting. This helps you estimate the expected life of the system and can support you plan for any problems with overheating or wear.

Accuracy

You’ll want to make sure that the actuator’s precision either meets or exceeds the needs of the system in terms of accuracy, uniformity of linear motion and backlash. Otherwise, you may run into some very large obstacles. Knowing accuracy requirements can help you avoid overpaying for an actuator that’s more finely tuned than needed.

Environment

Here’s the part that everyone forgets, operating environment. Will the actuator need to operate in extreme temperatures, around dangerous contaminants or harmful chemicals? While it may work fine at room temperature in dry air, many actuators would fail at 200º F ambient temperature or under exposure to corrosive acids, and it’s critical to plan for that.

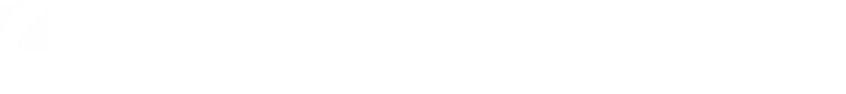

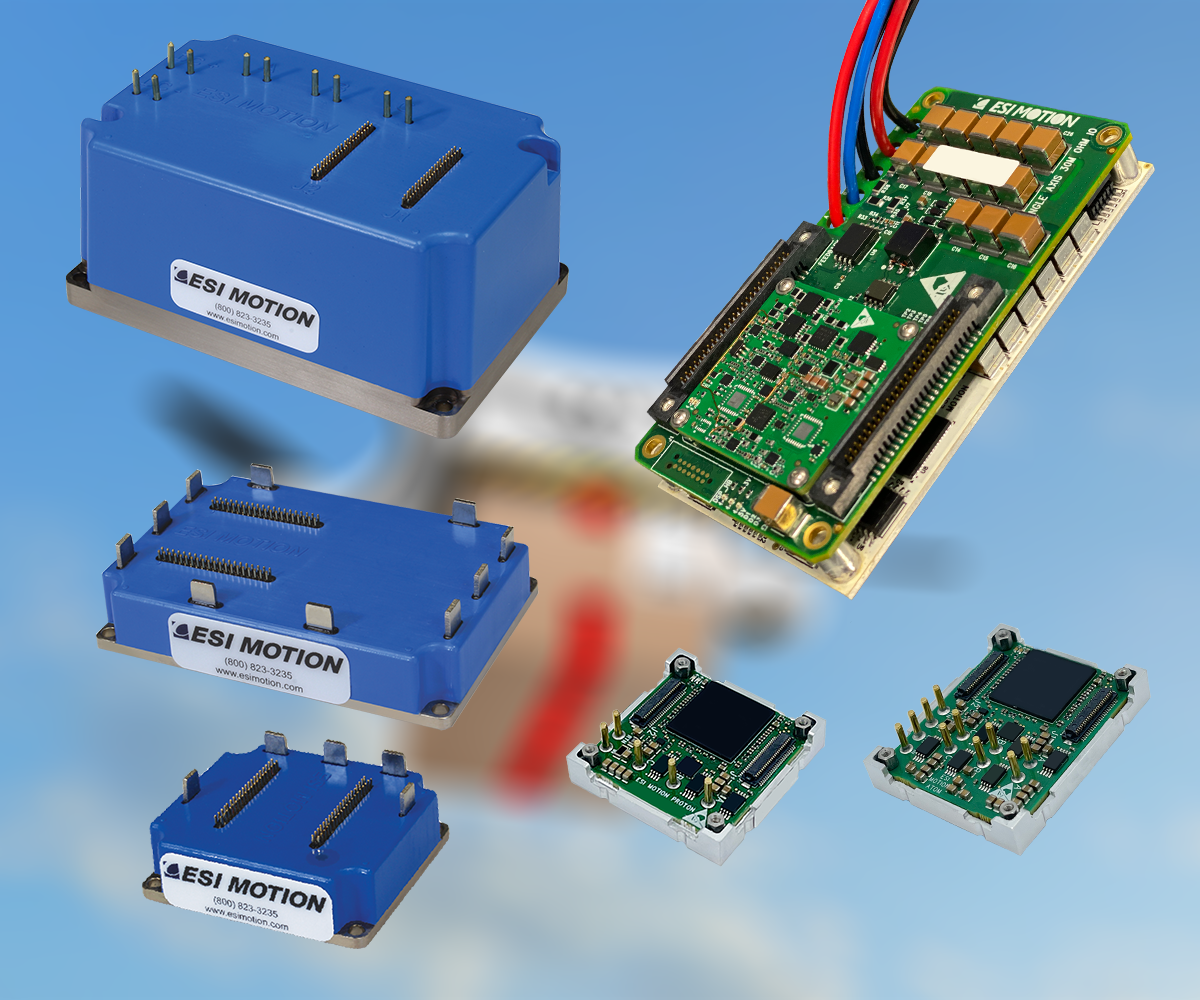

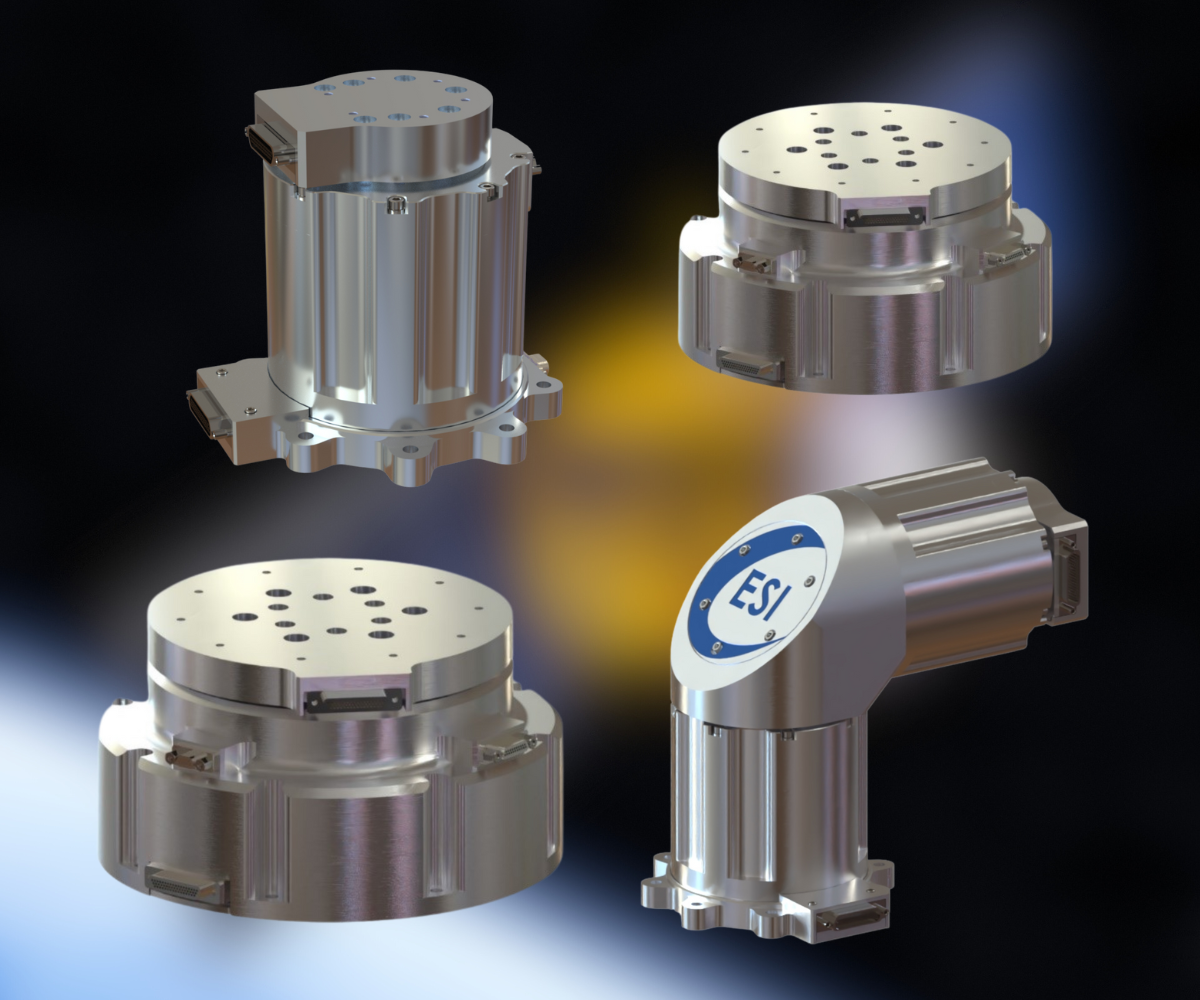

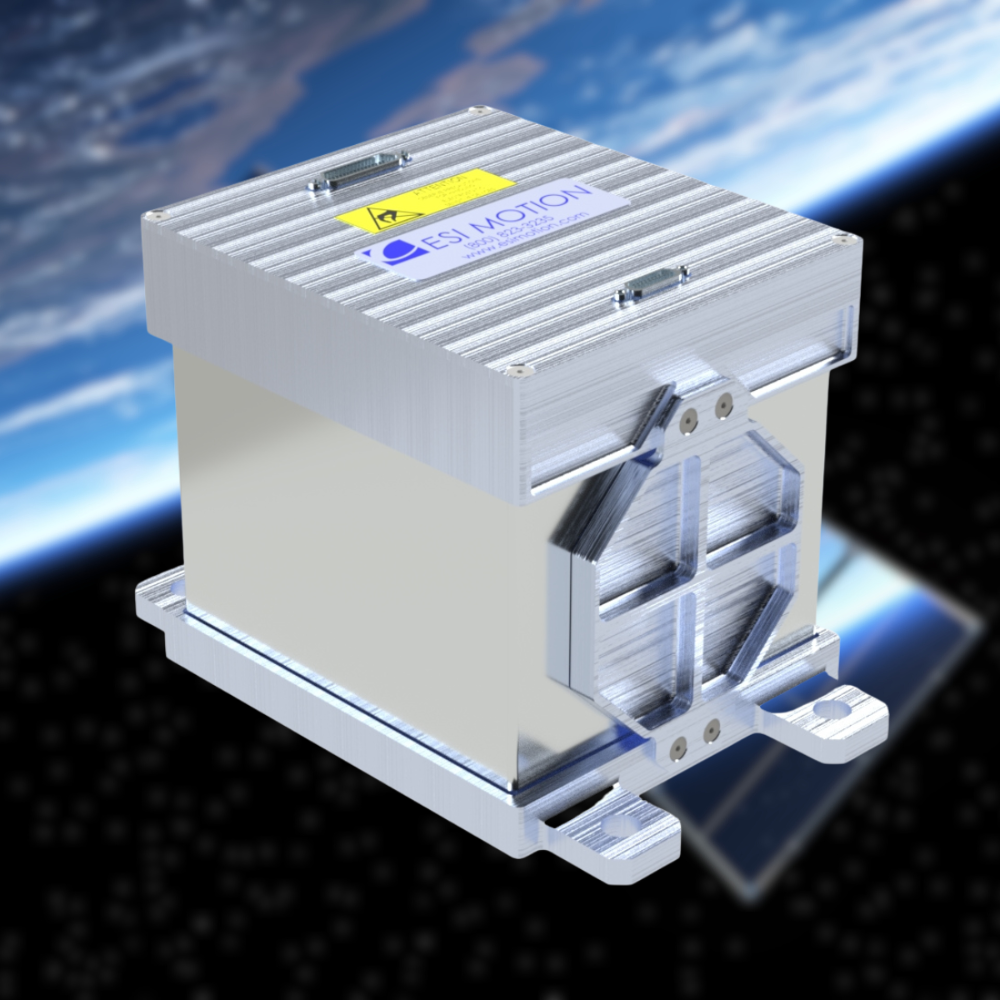

Contact Your Motor Control System Experts

Have more questions about selecting the right actuator or need a high performance servo drive to operate it? That’s what we’re here for. Feel free to call us at 800.823.3235, reach out to us at our contact page, or check out our line of durable, extreme environment servos. We can’t wait to hear from you, and we’ll see you back here for more tips on making motor control systems that work.