Space-Rated Servo Drives play a crucial role in space gimbals, offering a range of benefits that are vital for the precision and reliability required in space missions. Here are some key advantages:

1. High Precision and Control

Servo Drives in space gimbals offer precise control of motor movement, enabling the accurate positioning of payloads like sensors, cameras, and antennas. This precision is critical in space, where slight misalignments can lead to mission failure, such as incorrect satellite orientation or inaccurate data collection.

2. Radiation and Environmental Resistance

Space-Rated Servo Drives are specifically designed to withstand the harsh space environment, including exposure to extreme temperatures, radiation, and vacuum conditions. Conventional drives would degrade or malfunction under these conditions, but Space-Rated versions are Radiation-Tolerant and made from materials that can function reliably in such environments.

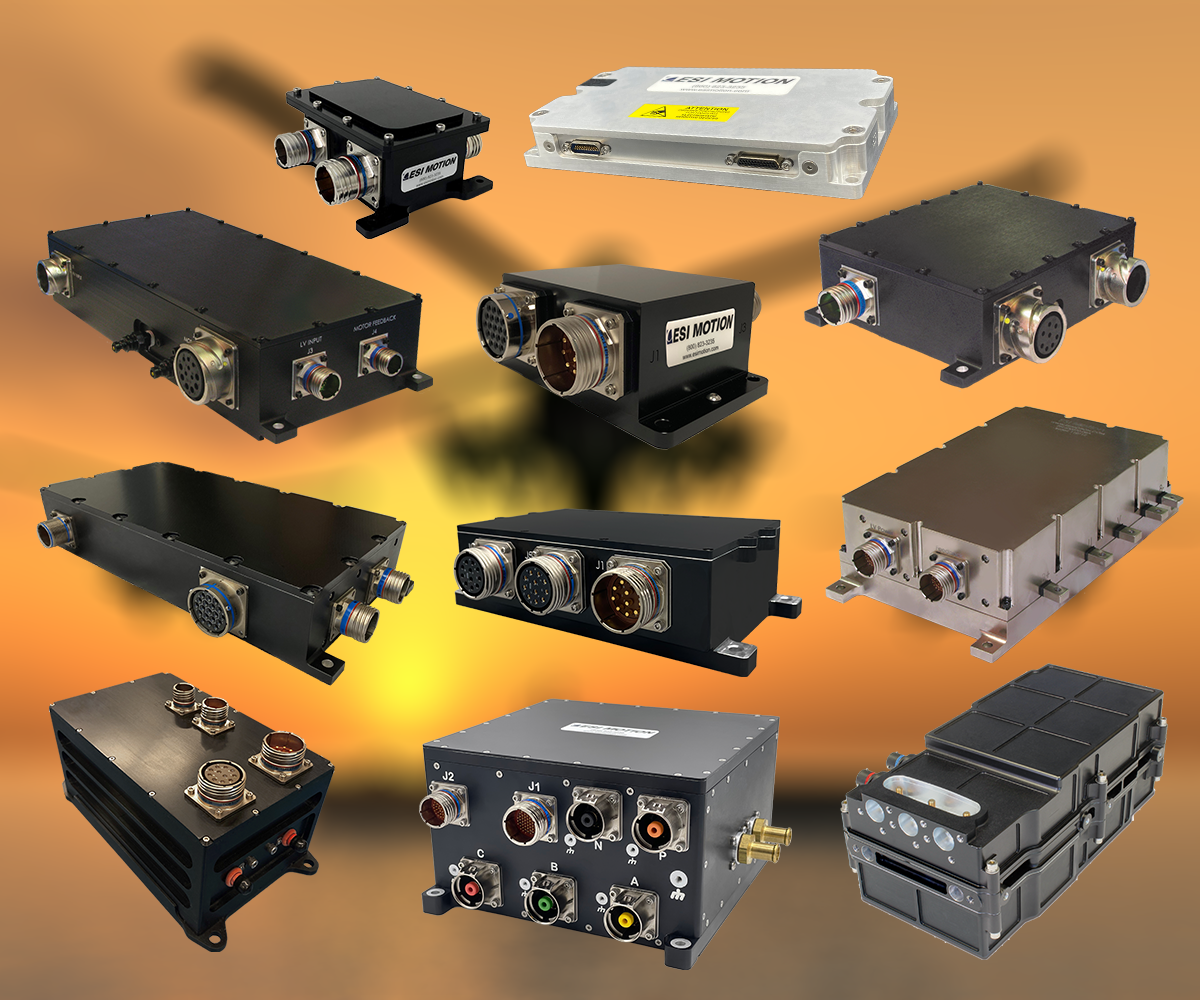

3. Reduced Weight and Size

Space missions are heavily constrained by weight and space. Space-Rated Servo Drives are often designed to be lightweight and compact, making them easier to integrate into space gimbals without compromising on performance. This reduction in size and weight translates into significant cost savings and efficiency in launching spacecraft.

4. Reliability and Longevity

Space missions often last for several years, so components like Servo Drives must function reliably over long periods without maintenance. Space-Rated Servo Drives are built with high-reliability components that offer long operational lifespans, ensuring that space gimbals can perform flawlessly for the duration of the mission.

5. Power Efficiency

Space-Rated Servo Drives are designed to operate efficiently with limited power supply. Spacecraft have finite energy sources, and optimizing the power consumption of components like gimbals is critical for mission success. The efficient operation of Servo Drives ensures that they use minimal energy while still delivering high performance.

6. Smooth Motion Control

Space-Rated Servo Drives enable smooth motion control in gimbals, minimizing vibrations and jitter. This is essential for space applications where stability and precise motion are required, such as tracking objects or conducting high-resolution imaging. The ability to achieve smooth, controlled movements is particularly beneficial for scientific instruments or communication systems aboard spacecraft.

7. Redundancy and Fault Tolerance

Space-Rated servo drives often include built-in redundancies and fault-tolerant mechanisms, which are crucial for space applications. If one component fails, others can take over, ensuring continued operation. This design aspect is essential for critical missions where repairs are impossible once the equipment is deployed in space.

8. Customization for Specific Mission Requirements

Space-Rated Servo Drives can often be customized for specific mission needs. This allows manufacturers to design Servo Drives that meet the exact requirements of a mission, including torque, speed, environmental resistance, and interface with other spacecraft systems.

Conclusion

The integration of Space-Rated Servo Drives into space gimbals ensures that they meet the rigorous demands of space missions. With high precision, environmental resilience, reliability, and power efficiency, these drives play a pivotal role in enhancing the performance and longevity of gimbal systems, ultimately contributing to the success of space exploration and satellite operations.

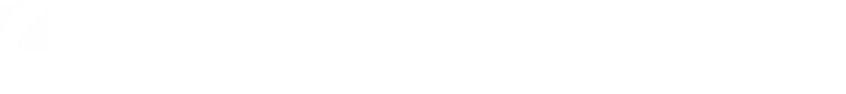

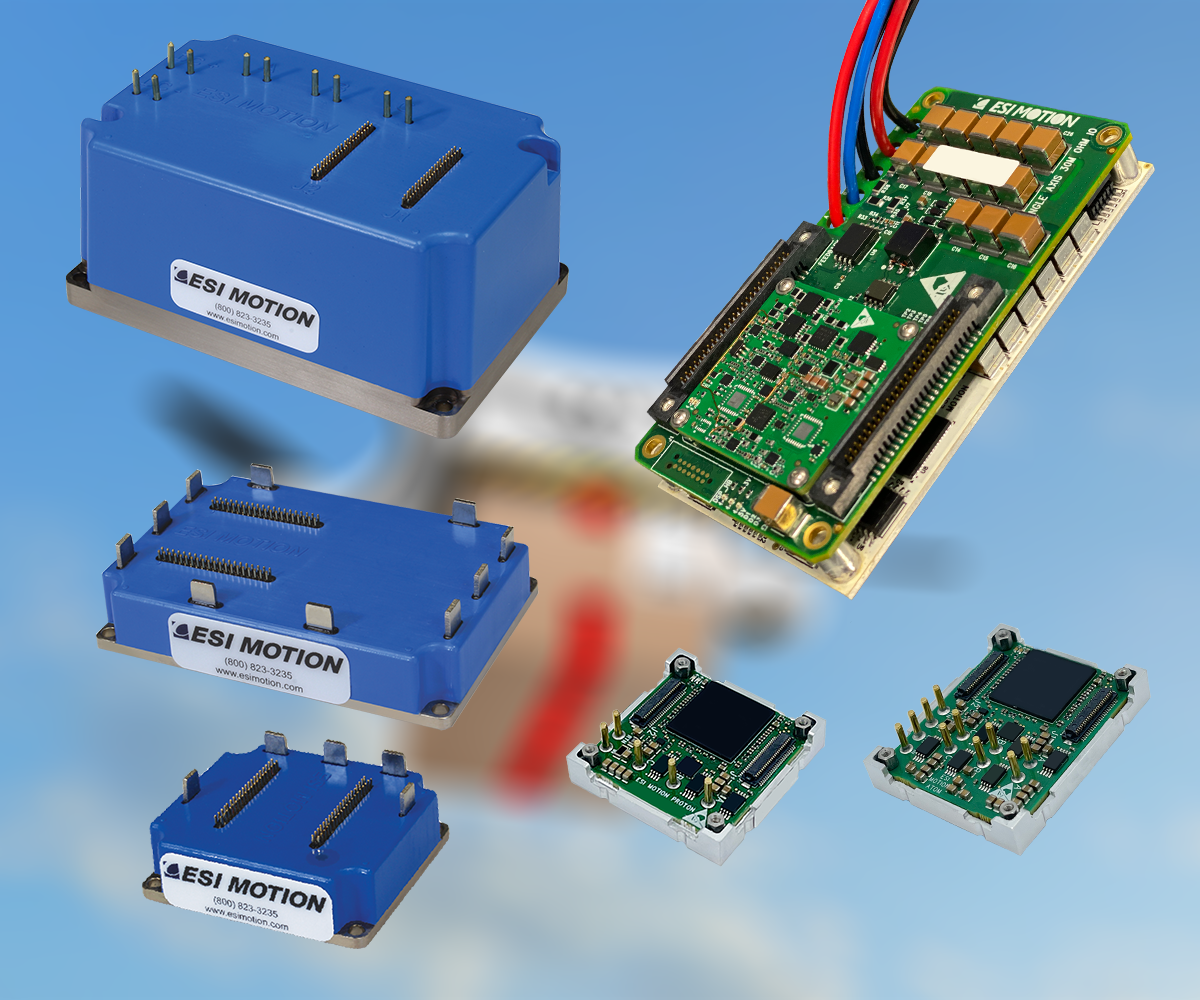

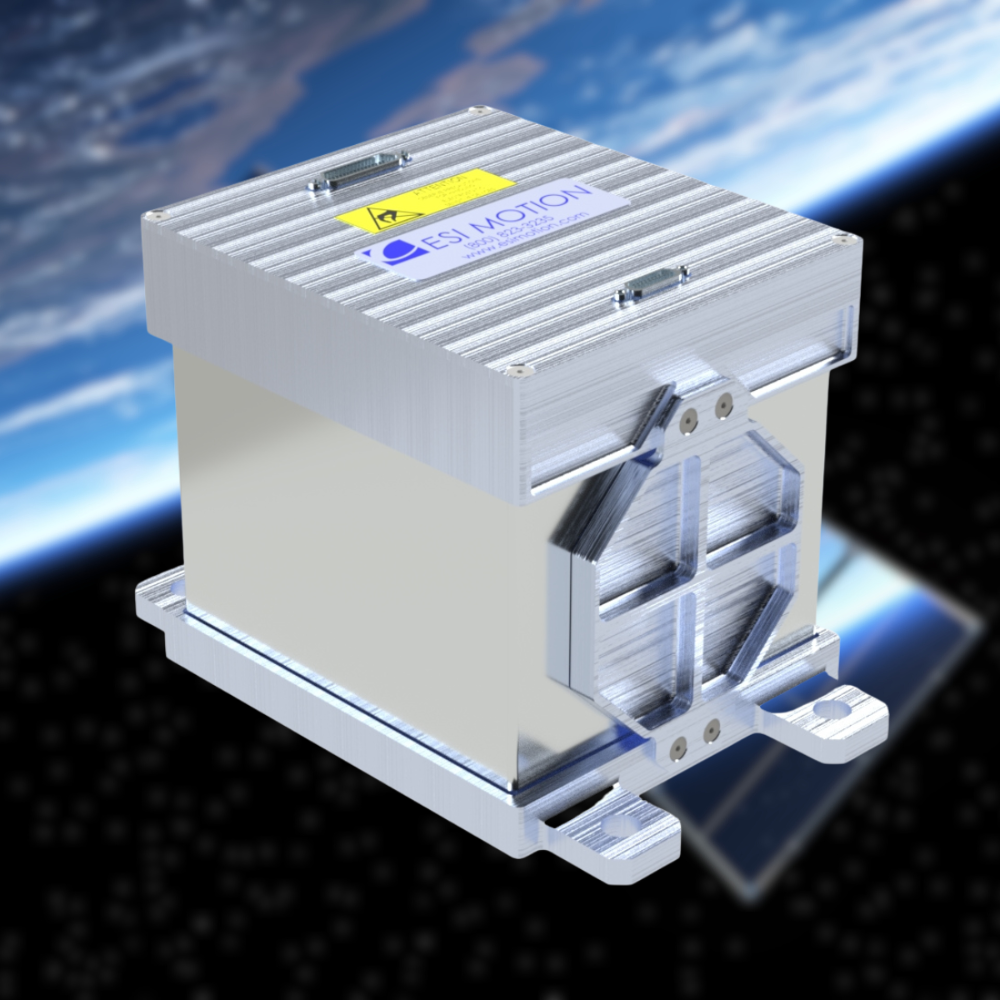

As an industry leader, ESI Motion possesses the know-how, experience, and support to help you achieve your mission goals while ensuring optimal performance and longevity for your equipment. We offer many solutions based on your needs, timeline and budget with Commercial Off-The-Shelf, Modified and Full Customization Servo Drive Systems! ESI Motion has years of experience providing motion control for a vary of Space Applications!

Contact ESI Motion by calling +1.800.823.3235 or email us at sales@esimotion.com.

If you’ve got any questions, we’ve probably got them answered here on our FAQ. If you need any technical support, our team is here to help.

Click Here to see more of our solutions.