Servo Drives in Space and Low Earth Orbit (LEO) Satellites

Servo drives are used in space satellites and lower earth orbit (LEO) satellites to control the movement of actuators, such as motors and gears, that are used to position and orient the satellite. They typically include a control circuit, a power amplifier, and a feedback mechanism to ensure precise control of the actuator.

In both space and LEO, servo drives must be able to withstand the harsh radiation environment, high vacuum, and extreme temperatures. Therefore, space-rated servo drives are typically made with radiation-hardened components and use redundant systems for increased reliability. They also tend to have a wider operating temperature range compared to servo drives used in terrestrial applications.

Radiation-tolerant parts are designed to withstand the high levels of radiation found in space. These parts are typically made of materials that can withstand ionizing radiation, such as silicon-on-insulator (SOI) or radiation-hardened (Rad-Hard) semiconductors. Additionally, these parts are often designed with redundant systems and fault-tolerance in mind to increase their chances of survival in a radiation environment. They also tend to have a wider operating temperature range compared to servo drives used in terrestrial applications.

However, because LEO satellites orbit closer to the Earth, they are subject to more intense radiation than satellites in higher orbits. This means that servo drives used in LEO satellites must be even more radiation-hardened and reliable than those used in higher orbits. Additionally, LEO satellites are also exposed to more atmospheric drag and need to consume more power to maintain their orbit, which can also affect the design of servo drives.

Space Applications for Servo Drives

The type of servo drives used in space satellites depend on the specific requirement of the mission. Some satellites use brushless DC servo drives, while others use stepper motor drives or linear motor drives. The choice of servo drive also depends on the specific application, such as pointing and stabilization or positioning and orienting of the satellite or payloads such as antennas, solar panels and cameras. LEO satellites are commonly used for a variety of missions such as earth observation, communication, and navigation, and so the requirement for the servo drives will vary depending on the payload and the mission. Some LEO satellites use precise pointing and control system for high-resolution imaging and communication, while other use coarse pointing for global coverage.

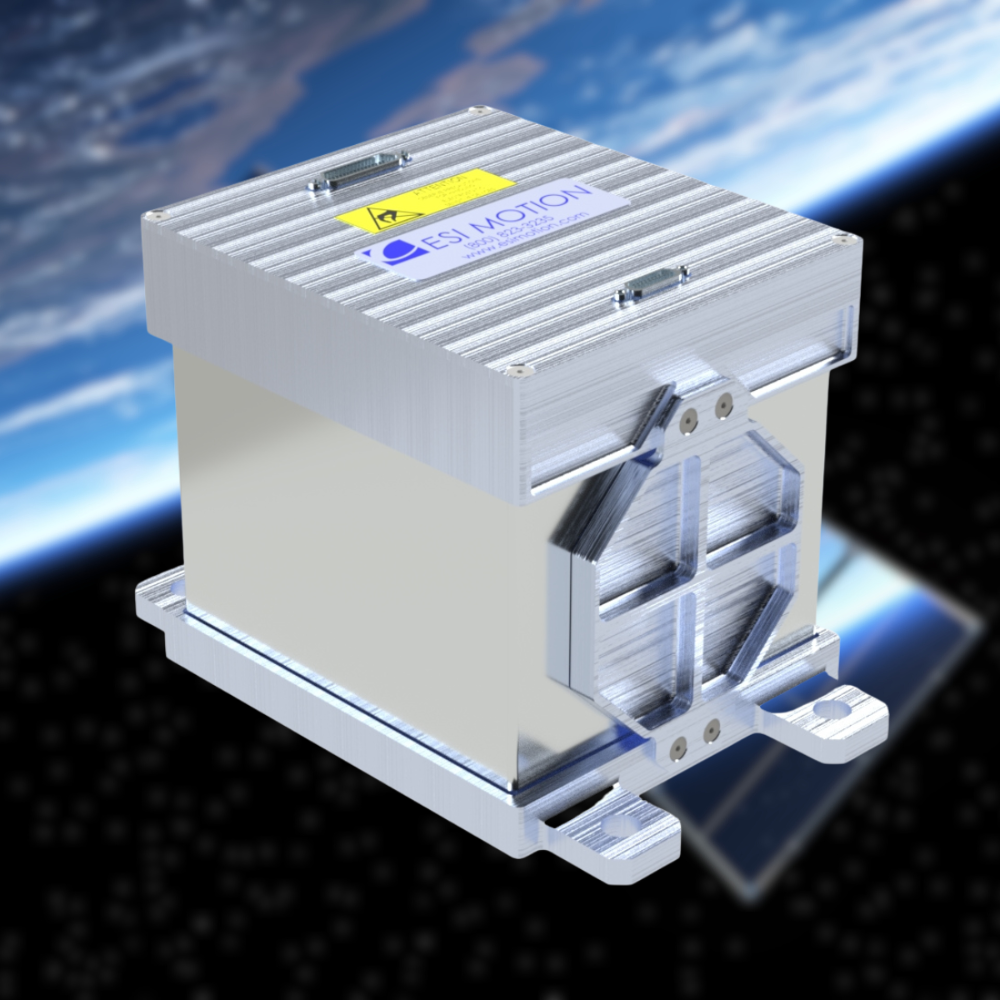

Due to their high-performance standards, harsh temperatures, and atmospheric and G-force pressures, space exploration and aeronautical operations present challenging technical challenges. In Low Earth Orbit (LEO) and outer-space applications, ESI Motion has established itself as the market leader in providing precise servo drive systems that are dependable in even the toughest situations.

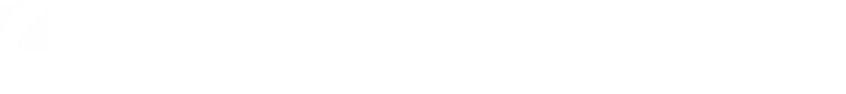

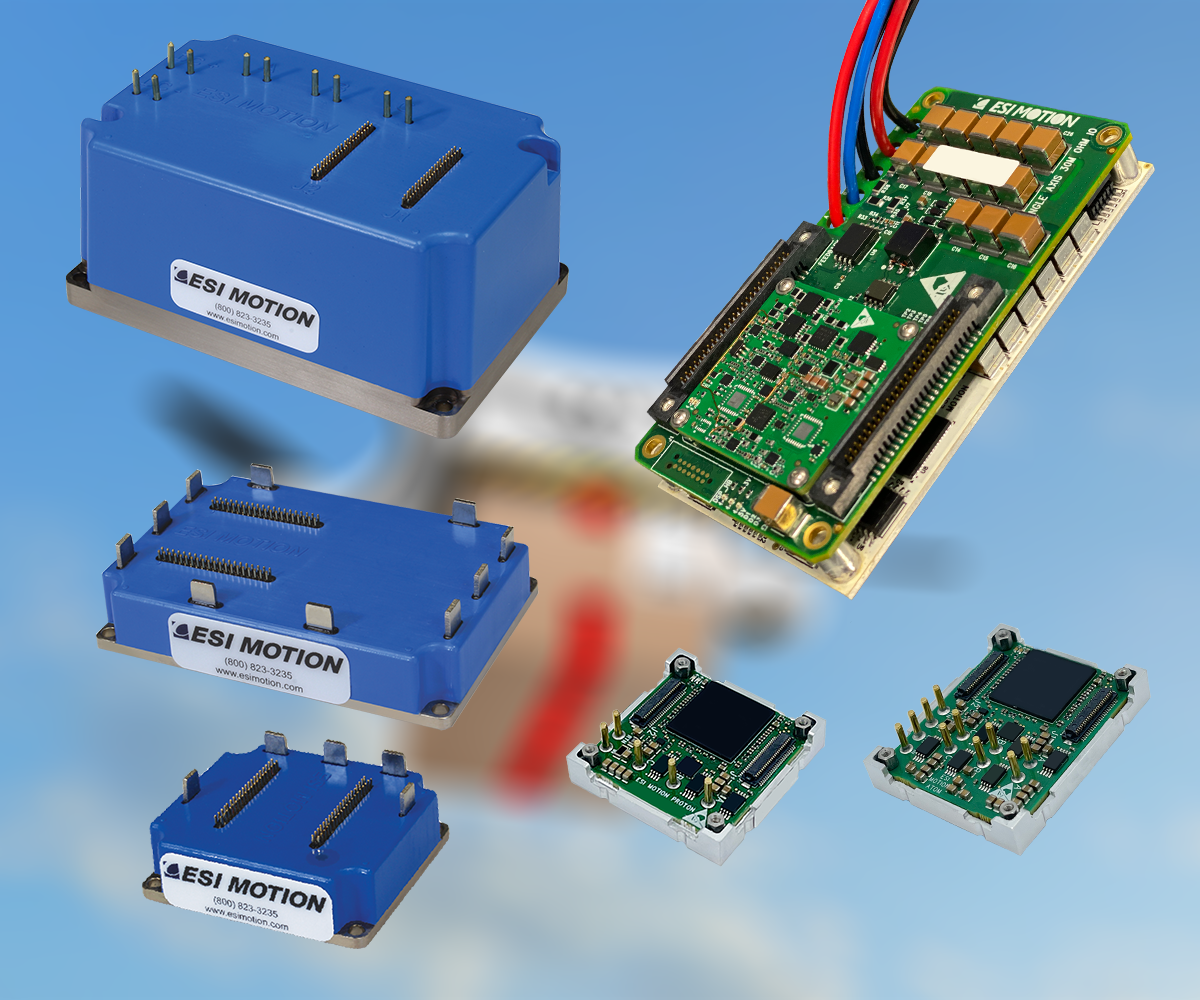

We manufacture some of the most cutting-edge servo drives available on the market for mission-critical space system applications. Regardless of how challenging the working environment may be, every one of our servo drives is designed to consistently give best-in-class performance.

How Servo Drives Power Exploration and Discovery

The ultimate engineering challenge is space travel, and the engineers at ESI Motion have collaborated with several research facilities, laboratories, and other organizations to offer motor control systems that exactly satisfy the special needs of mission-critical applications.

The most cutting-edge technical applications can be supported by our team with unmatched expertise. Extreme conditions must be met for the motor control systems of vehicles and other space exploration equipment to function. These systems' operational parameters include things like:

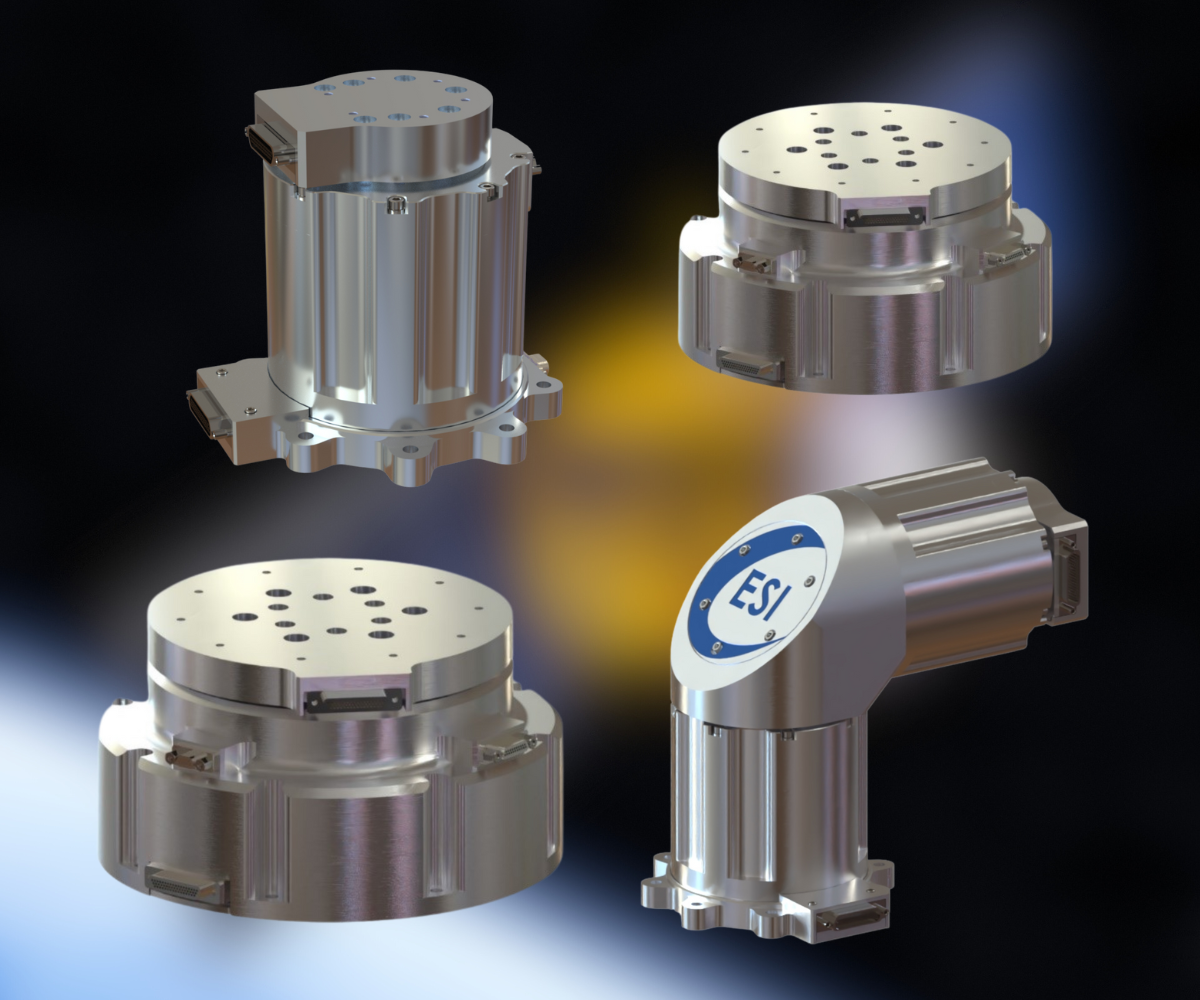

Size and weight efficiency are vital across almost all servo drive applications, but nowhere is it more critical than space applications like low Earth orbit (LEO) satellites. ESI Motion built the revolutionary NOVA servo drive specifically to excel against the unique challenges of LEO systems. And now, SuperNova has been built specifically to excel in both space and low earth orbit systems. The journey from Earth’s surface to low Earth orbit and beyond is not a smooth one, and it subjects onboard components to extreme shocks, vibration, and high varying levels of radiation. The NOVA and SuperNova servo drives are radiation tolerant and contain shock-resistant housings to maintain optimal performance in high-vibration vacuum environments.

Designing Servo Drives that Power Aerospace Systems

ESI works with the aerospace industry to develop innovative product solutions to meet their unique operating parameters. Aerospace operations are conducted in the upper atmosphere or space. Aerospace servo drives and motion control systems have been developed for some of the world’s most advanced aerospace vehicles that operate in the most demanding environments. Our rugged servo modules series is a line of light and compact controllers ideal for defense, aerospace, automotive, and robotics.

ESI Motion’s servo drives are used for precise operations, speed, energy efficiency, and outstanding dependability — that is why they have been selected for inclusion in some of the most technically advanced systems working today.

Let ESI Motion Help You with the Demands of Space Systems

The servo drives that support many other industries, such as military defense, energy applications, and medical technology, are leading the way in space systems. Our team is ready to assist you with innovative solutions in space systems. To learn more about the modules, products, and engineering services we provide, please contact ESI Motion today by calling +1.800.823.3235 or email sales@esimotion.com. You can also reach out to us on our contact page.