Servo drives play a crucial role in actuation systems, particularly in the field of motion control and automation. Actuation refers to the process of controlling and moving mechanical systems, such as motors and actuators, to achieve a desired output.

Here's how servo drives contribute to actuation:

1. Motor Control:

Power Amplification: Servo drives amplify the control signals from a controller to provide the necessary power to drive the motor. This amplification ensures precise and efficient control over the motor's movement.

Feedback Mechanism: Servo drives typically work in conjunction with feedback devices such as encoders or resolvers. These devices provide real-time information about the motor's position, speed, and direction. The servo drive uses this feedback to make continuous adjustments, ensuring accurate and consistent motion.

2. Precision and Accuracy:

Closed-Loop Control: Servo systems operate in a closed-loop control configuration. The feedback from the motor is constantly compared with the desired position or speed, and the servo drive adjusts the motor's output to minimize any errors. This closed-loop control system ensures high precision and accuracy in actuation.

Dynamic Response: Servo drives offer fast and precise response times. This is crucial in applications where rapid and accurate movements are required, such as in robotics, CNC machines, and other automated systems.

3. Flexibility and Adaptability:

Parameter Tuning: Servo drives allow for the tuning of various parameters such as gain, bandwidth, and damping. This flexibility enables the optimization of the system's performance for different applications and operating conditions.

Adaptive Control: Some advanced servo drives feature adaptive control algorithms that can adjust parameters in real-time based on changing load conditions. This adaptability ensures optimal performance even in dynamic environments.

4. Energy Efficiency:

Energy Recovery: Servo drives may incorporate regenerative braking systems, where excess energy generated during deceleration or braking is fed back into the power supply. This regenerative capability enhances energy efficiency in the system.

5. Safety Features:

Overload Protection: Servo drives often include features to protect the motor and associated components from overloads. This can include current limiting, temperature monitoring, and other safety measures.

In summary, servo drives are instrumental in actuation systems by providing precise control, feedback mechanisms, adaptability, and safety features. Their integration enhances the overall performance and efficiency of motion control applications across various industries.

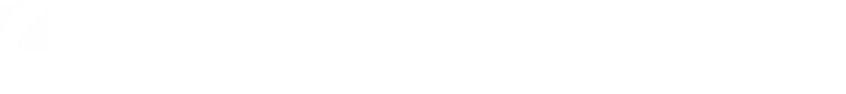

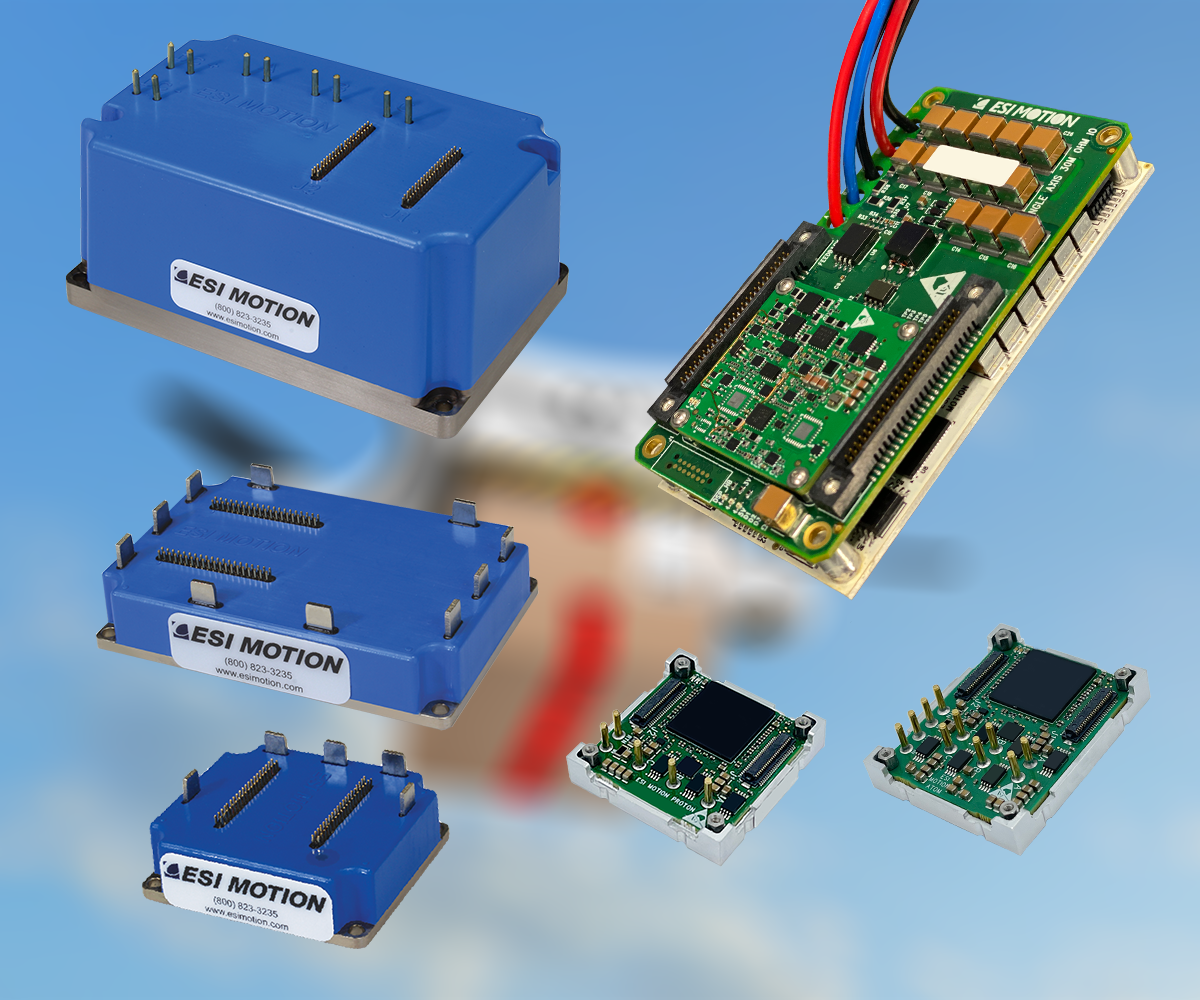

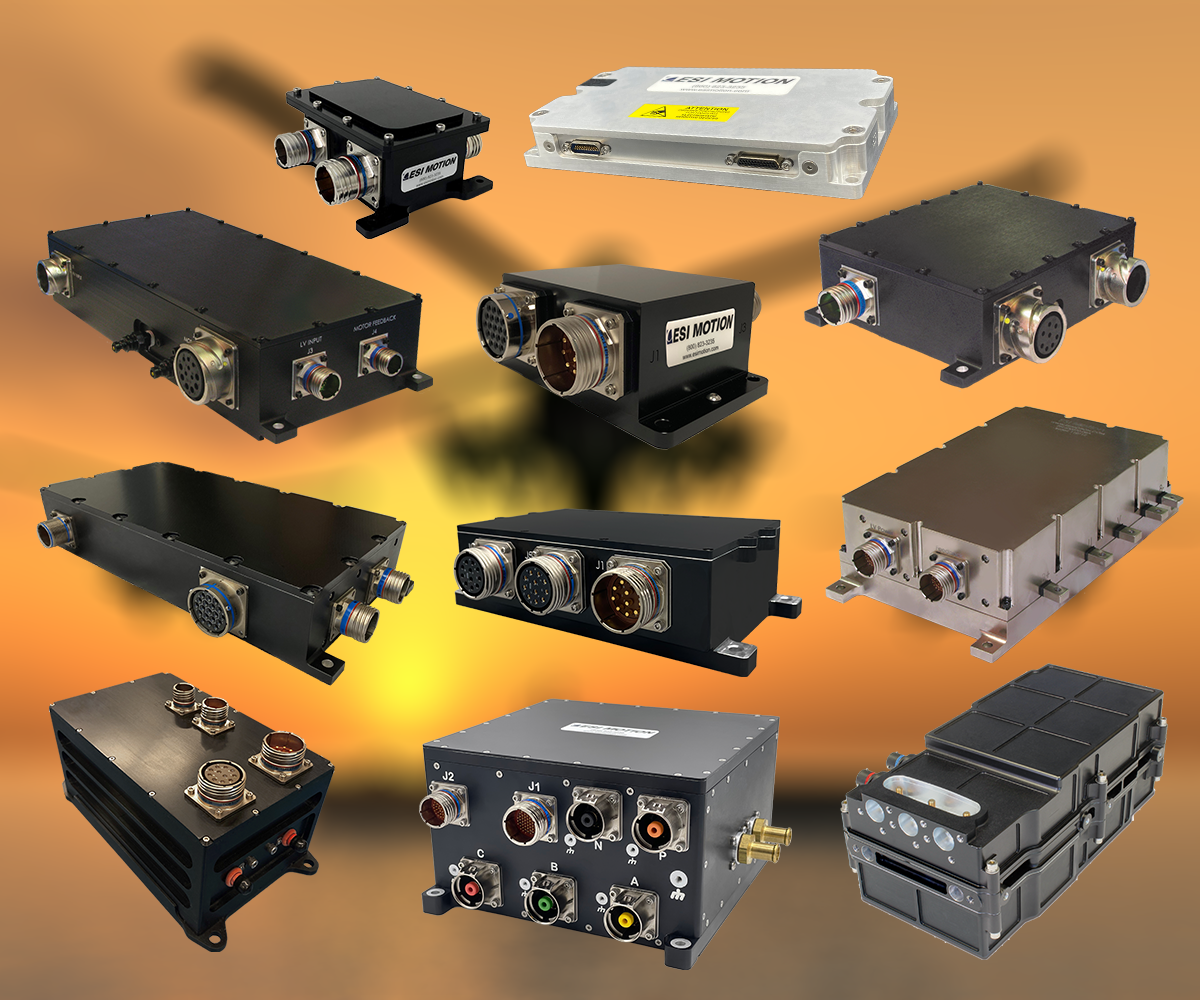

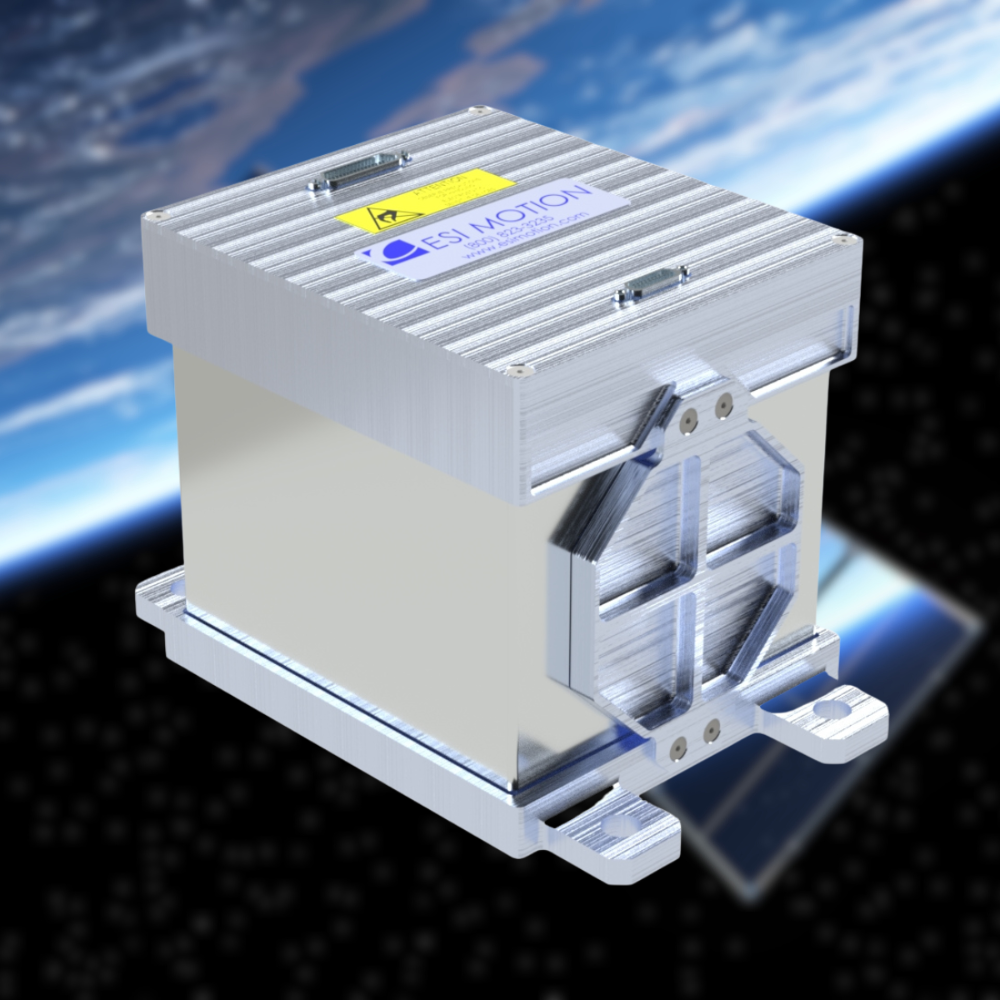

ESI Motion understands how crucial servo drives are for actuation. From partnerships with Actuator Companies to our COTS products being fully integrated into Customer actuation products to full customized, flight-critical actuator products; ESI Motion has the experience and partnerships to fulfill your actuator needs. We have been apart of program success from LEO & GEO Space, Defense programs around the world and Commercial programs such as robotics, UAVs and more.

Contact Us Today

As an industry leader, ESI Motion possesses the know-how, experience, and support to help you achieve your mission goals while ensuring optimal performance and longevity for your equipment.

Contact ESI Motion by calling +1.800.823.3235 or email us at sales@esimotion.com. We can help you find the right solution for your actuation system needs.

If you’ve got any questions, we’ve probably got them answered here on our FAQ. If you need any technical support, our team is here to help.

Click Here to see more of our solutions.

Check out our products and their capabilities here.