A servo controller and a motor work together to control the position, speed, and sometimes torque of a mechanical system. Let's break down the relationship between a servo controller and a motor:

1.Servo Motor:

• A servo motor is a type of motor designed for precise control of angular or linear position.

• It consists of a DC or AC motor, feedback device (such as an encoder or resolver), and a control system.

• The feedback device provides information about the current position, speed, or other relevant parameters of the motor.

2.Servo Controller:

• The servo controller is a device or a subsystem responsible for controlling the motion and behavior of the servo motor.

• It processes signals from external sources or a user interface and generates control signals to drive the motor.

3. Feedback System:

• The feedback system is crucial for the servo system's closed-loop operation. The most common feedback devices are encoders or resolvers.

• The feedback signal helps the controller understand the actual position or speed of the motor.

4. Closed-Loop Control:

• The servo controller continuously compares the desired position (setpoint) with the actual position (feedback) from the motor.

• Based on this error signal (difference between setpoint and feedback), the controller adjusts the motor's behavior to minimize the error.

5.Control Algorithms:

• Proportional-Integral-Derivative (PID) control is a common algorithm used in servo controllers. It adjusts the motor's output based on the proportional, integral, and derivative terms of the error signal.

• The proportional term responds to the current error, the integral term addresses accumulated past errors, and the derivative term anticipates future errors.

6. Communication Interface:

• The servo controller often has communication interfaces (e.g., PWM - Pulse Width Modulation) to receive control signals from external devices such as microcontrollers, PLCs (Programmable Logic Controllers), or computers.

7. Power Amplification:

• The servo controller amplifies the control signals to provide the necessary power to drive the motor.

• It may also incorporate power electronics to convert the control signals into the appropriate voltage and current levels for the motor.

8. Applications:

• Servo systems are widely used in robotics, CNC machines, industrial automation, automotive systems, and other applications where precise control of motion is essential.

In summary, the servo controller and motor form a closed-loop control system where the controller adjusts the motor's behavior based on feedback signals to achieve and maintain the desired position, speed, or torque. This precise control is crucial for various applications requiring accuracy and responsiveness in motion control.

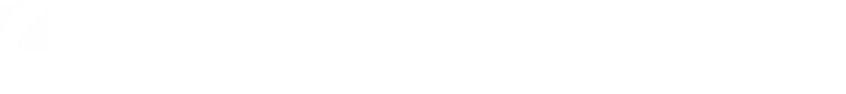

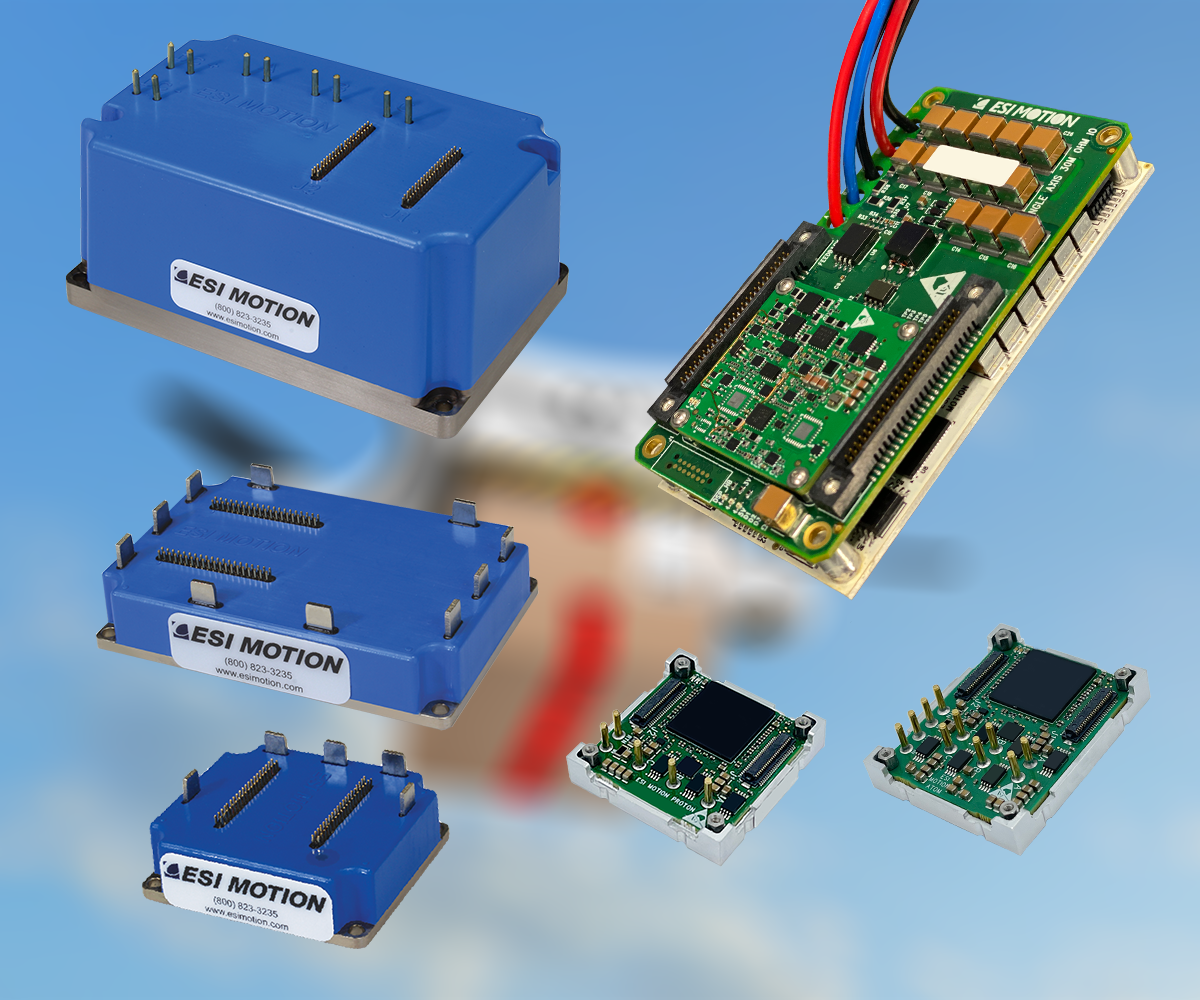

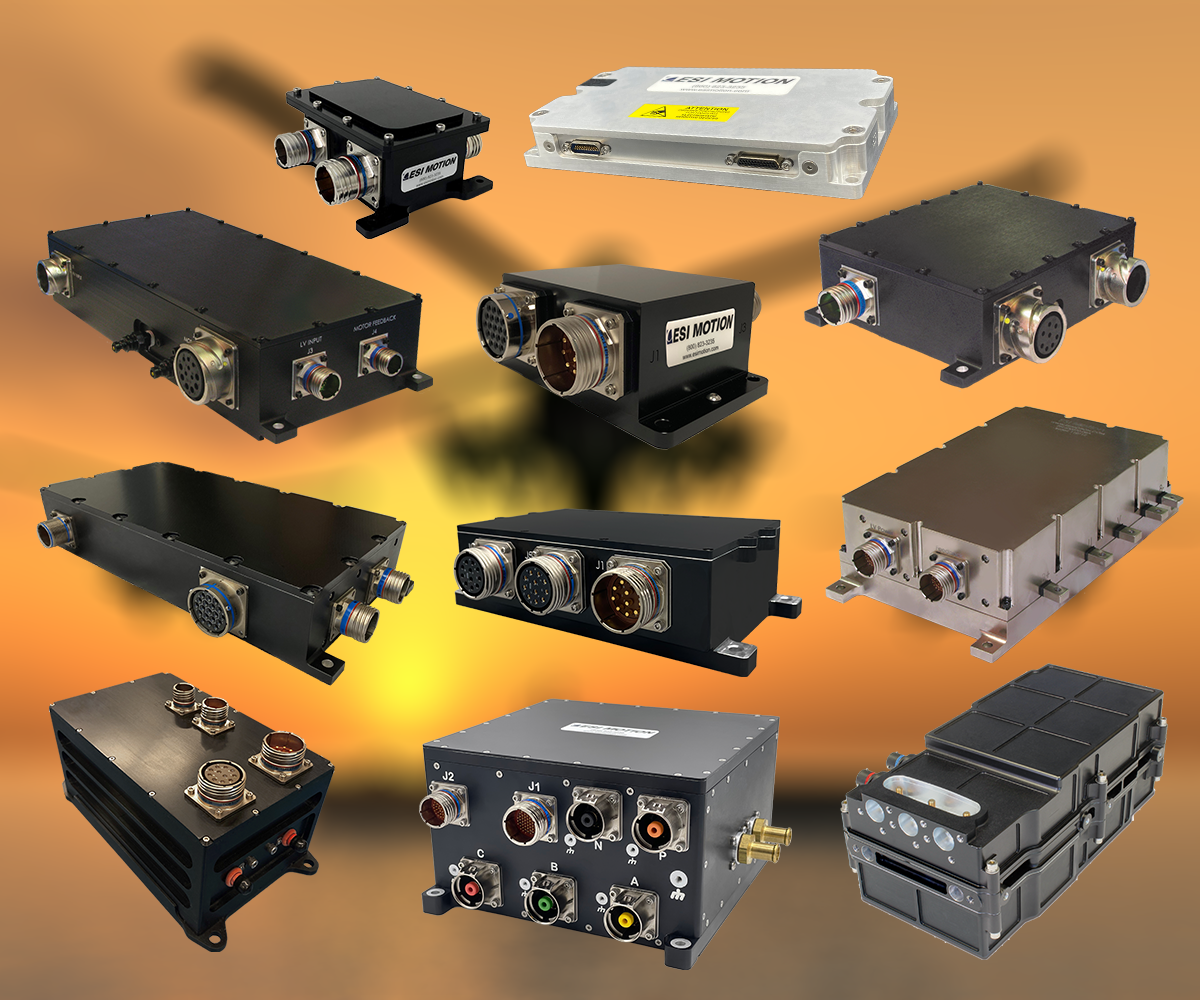

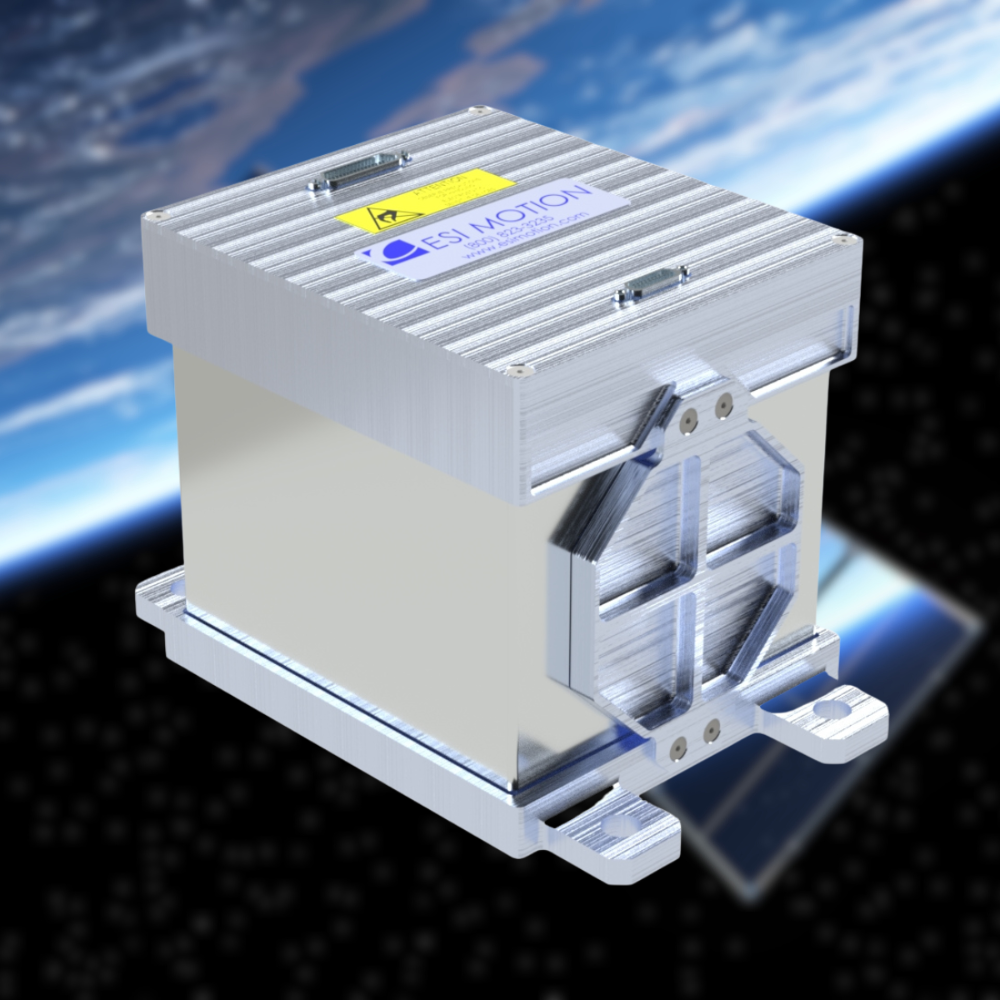

ESI Motion has emerged as an industry leader in servo controllers with years of experience providing motion control for applications on Land to under the Sea to the Aerospace and Space. We have the knowledge and know-how to support your mission application from beginning to end while offering Commercially Off The Shelf (COTS) products to Modified projects to full Customize Products to specifically fulfill your needs.

Your Motion Controllers are designed Ruggedized to operate effectively and efficiently in the harshest environments while working with your motors. Whether your Motor is DC, AC or a Stepper Motor, ESI Motion has to your solution.

To learn more, feel free to Contact Us Here! You can also email us at sales@esimotion.com or by giving us a call at +1.800.823.3235. We can help you find the right solution for your application needs!