Faster than a speeding bullet? Maybe. Like the man of steel, ESI Motion systems are made to withstand extreme heat, vibration, lightning strike, submersion, and the occasional explosion while running at breaking speeds.

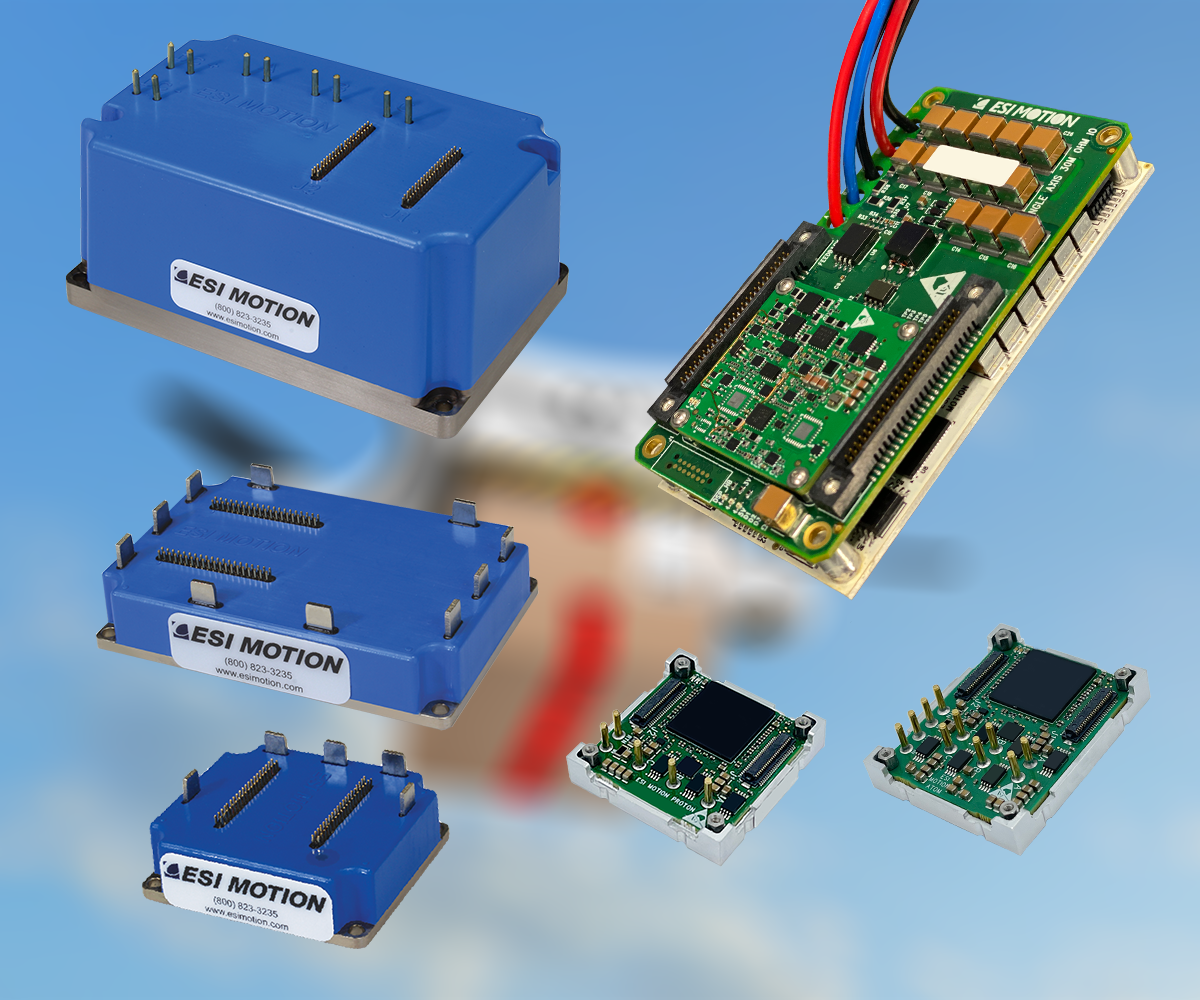

ESI Motion, headquartered in Simi Valley CA, is proud to support the men and women of our U.S. Armed Forces with cutting-edge electronics technology. Our motor control and power conversion technology is specialized for extreme environments, ideal for defense, aerospace, energy, oil and gas, robotics, and other specialized rugged applications.

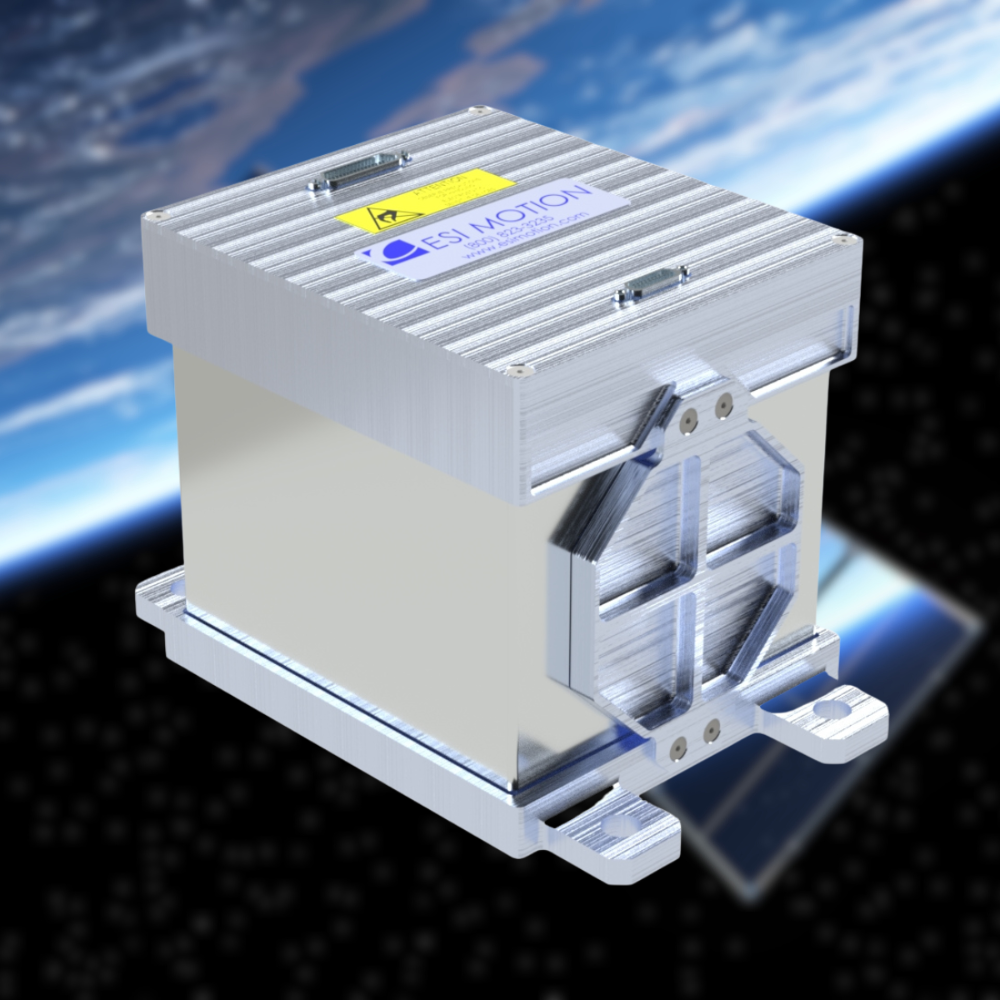

Recognizing the competitive need for higher performance off-the-shelf electronics, ESI was established in 2004 by an American family of engineers to focus exclusively on next generation motor control technology. From there, ESI quickly grew into a national and global supplier by providing our clients with incredibly small, powerful, cost-effective, and reliable systems.

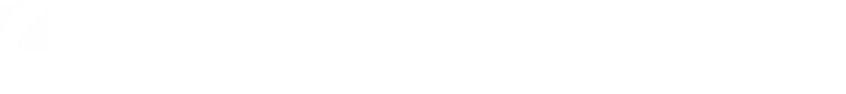

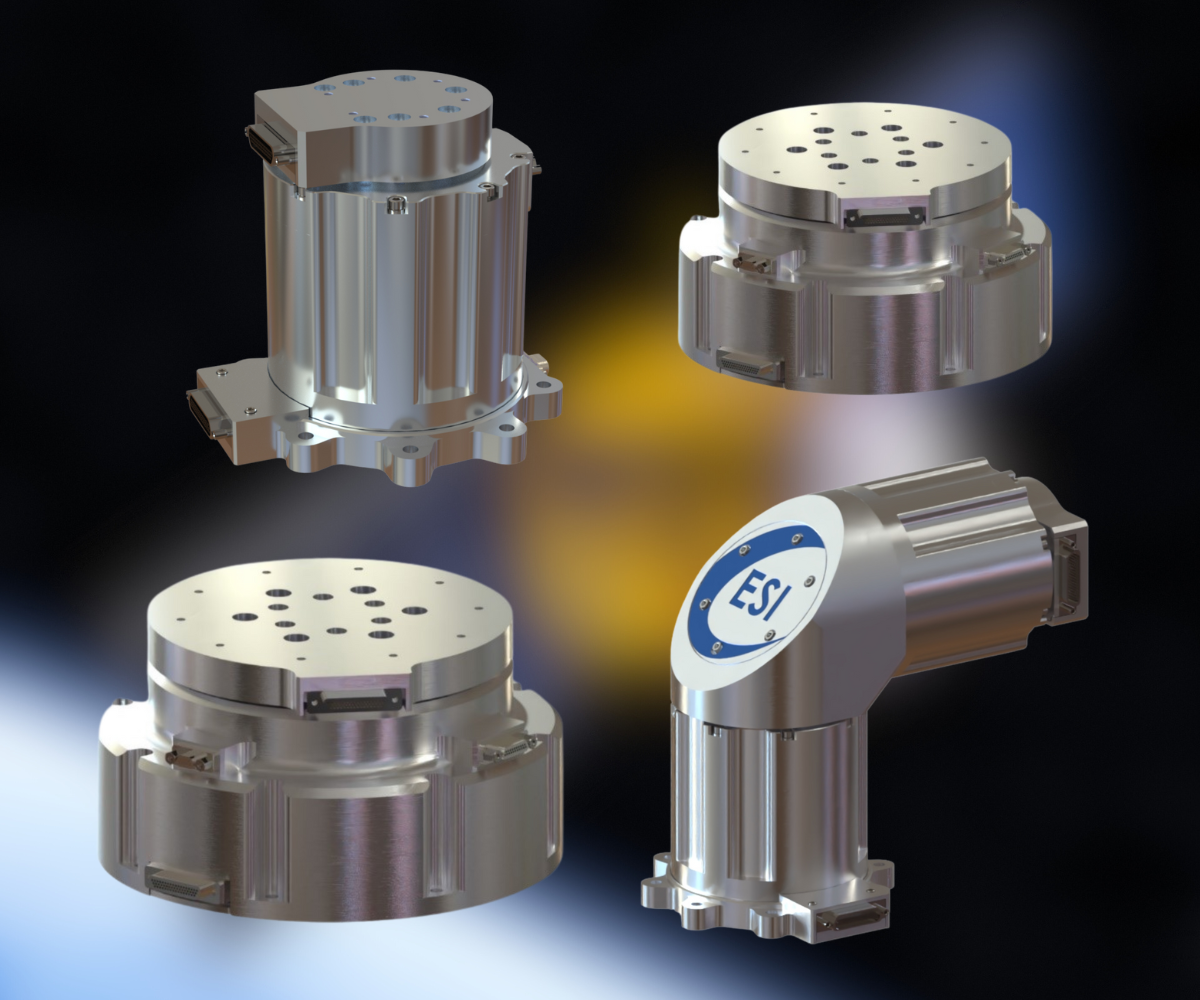

Our motor control electronics are designed to be modular, “plug and play” in nature, founded on a core of control hardware and software that have been fielded over a generation. Our most recent servo control module, the Mighty Mite is smaller than a deck of cards (2” x 3” x 0.6”), is dual axis and aerospace ready, with a wide temperature range of -55°C to 100°C. This extremely lightweight controller is the only dual axis drive of this size on the market today. All ESI solutions include a user-friendly PC interface with revolutionary system visibility that simplifies testing and system-level integration.

Recently, we have been privileged to be a part of several incredible endeavours for Army ground vehicle, space vehicle, and race car applications. We are pleased to have provided the flight wing flap actuator drives in the recent successful drop test of the Dream Chaser sub-orbital space vehicle. Previous to meeting ESI, our customer on this program found themselves in a difficult situation, having to potentially delay their drop test by almost a year. After contacting ESI, we were able to help them keep their drop test schedule by developing, building, and delivering nearly a dozen modified off-the-shelf, Fly-by-Wire controllers in 3 months. Earnie Beem, company founder, announced, “Our company was proud to help our client meet their goal and to be part of such an important American achievement.”

ESI was also very proud to have supported the Stryker Upgrade Program. This was yet another example of ESI’s ability to quickly deliver modified controllers – we delivered 3 completely different types of modified controllers in 6 months.

Anticipating the need for high-power density solutions, ESI was a pioneer in providing 600 VDC servo drive systems for military vehicle applications. Our latest off-the-shelf lines have expanded into distinct higher power, high temperature, and high speed lines.

Forward thinking and innovative solutions drive our technological focus, while safety and efficiency drive our commitment to quality.

Catering to customers in defense, aerospace, automotive, and specialized industrial industries provides a technological advantage through leveraging and applying experience form a widely diversified client base. Working knowledge of military and commercial standards benefits both disciplines, with insight gained from cross pollination of technology.

ESI appreciates the challenge of satisfying a need long desired in the defense industry – the ability to deliver rugged, lightweight, highly capable servo drive systems, in compliance to a very time and cost sensitive program schedules is our specialty. We look forward to having the opportunity to continue protecting, serving, and supporting our U.S. Armed Forces.