Cooling methods for servo drives are crucial to ensure the proper functioning and longevity of these electronic components. The choice of cooling method depends on factors such as the power rating of the servo drive, environmental conditions, and specific application requirements. Here are some common cooling methods for servo drives and their benefits:

Air Cooling

Method: Air cooling involves using fans or natural convection to dissipate heat from the servo drive.

Benefits: Cost-effective and simple implementation.

Suitable for low to moderate power applications.

No need for additional cooling fluids or complex systems.

Liquid Cooling

Method: Liquid cooling uses a coolant, such as water or a specialized liquid, to transfer heat away from the servo drive.

Benefits: Higher thermal efficiency compared to air cooling.

Better heat dissipation, allowing for smaller and more compact designs.

Suitable for high-power applications where air cooling may be insufficient.

Forced Convection

Method: Forced convection involves using fans or blowers to actively circulate air around the servo drive, enhancing heat dissipation.

Benefits: Improved cooling efficiency compared to natural convection.

Suitable for applications where higher airflow is necessary.

Heat Sinks

Method: Heat sinks are passive cooling devices that absorb and dissipate heat from the servo drive by increasing the surface area for heat transfer.

Benefits: Simple and reliable. Often used in conjunction with other cooling methods for enhanced performance.

Combination Methods

Method: Some applications may use a combination of cooling methods to optimize thermal management. For example, a servo drive might employ both air cooling and liquid cooling in different sections based on power density and thermal requirements.

Benefits: Offers flexibility to tailor the cooling solution to specific needs.

Allows for optimization of cooling efficiency in different areas of the servo drive.

Enclosure Design

Method: The design of the servo drive enclosure itself can influence cooling. Well-designed enclosures with proper ventilation and heat dissipation features can enhance the overall cooling performance.

Benefits: Efficient cooling without relying solely on external cooling methods.

Can be particularly important in harsh environments.

Choosing the Method Best for You

Choosing the appropriate cooling method depends on the specific requirements of the application, such as power density, ambient temperature, and space constraints. Proper thermal management ensures the reliability and optimal performance of servo drives in various industrial and automation settings.

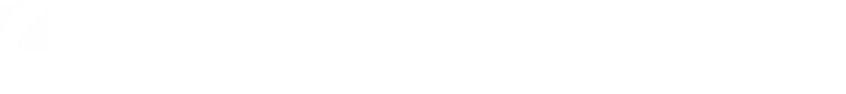

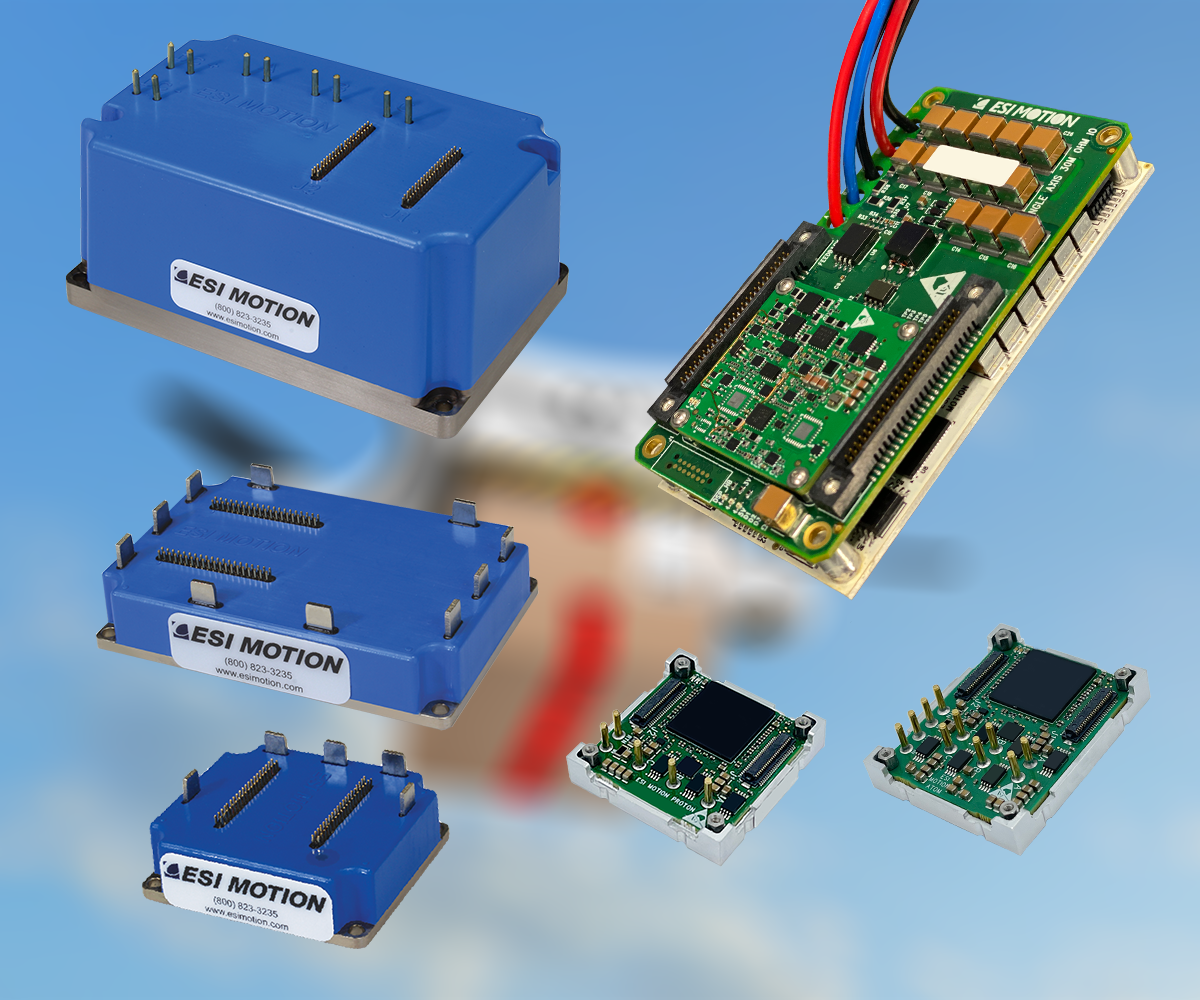

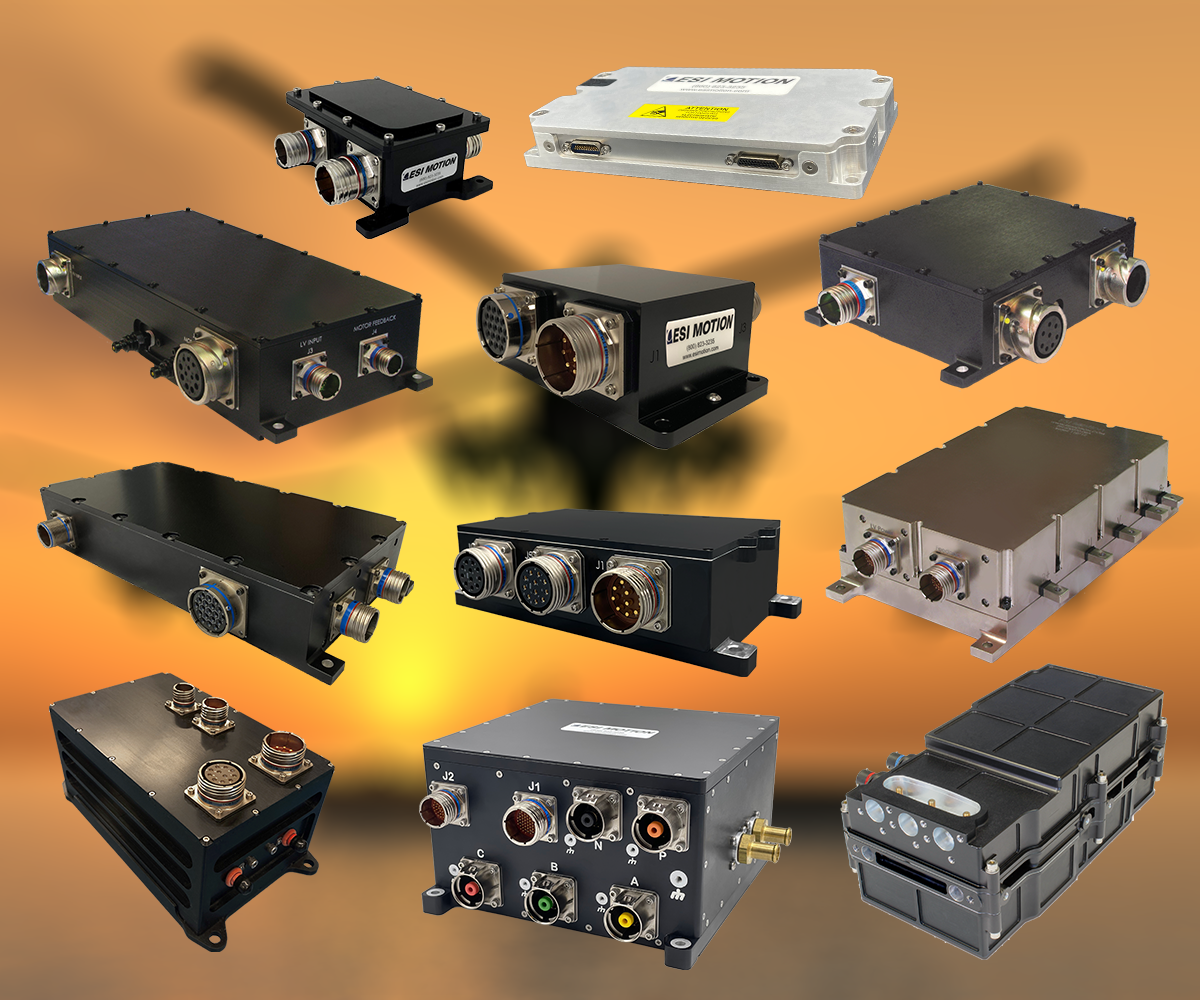

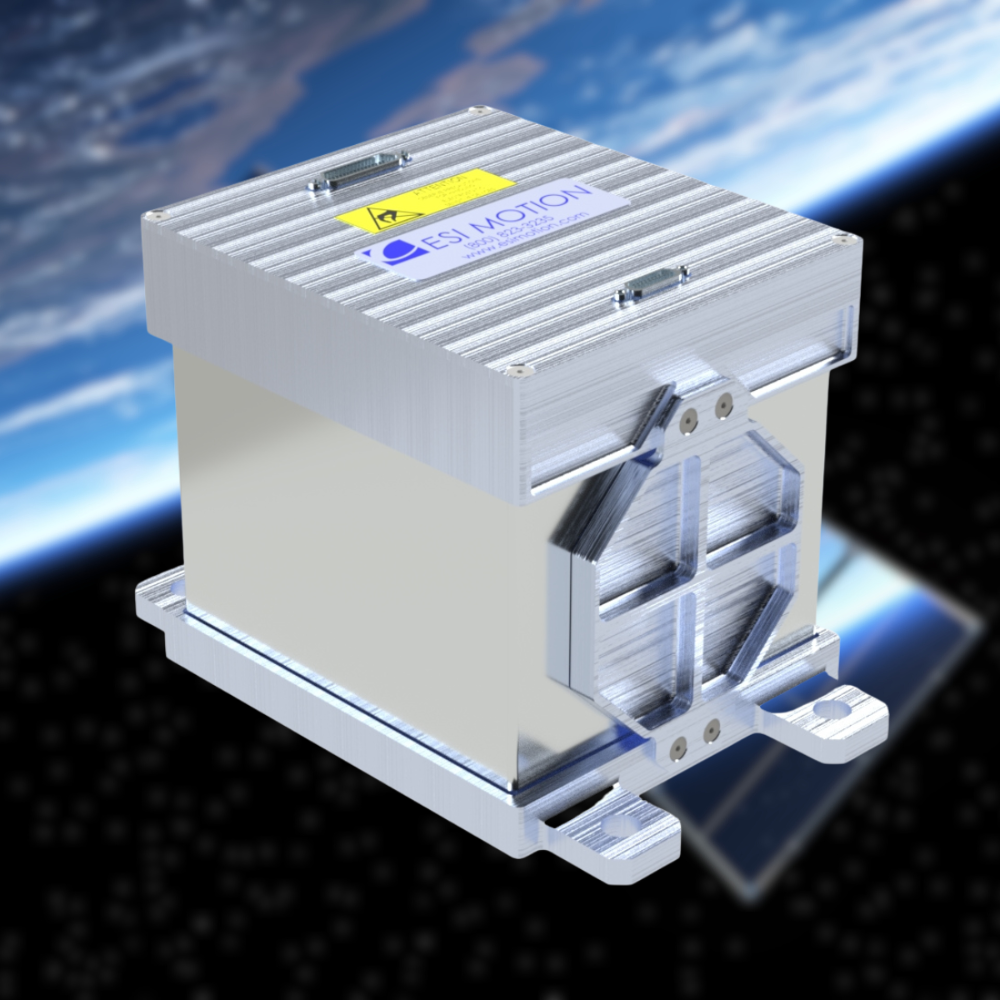

At ESI Motion, we can help you achieve the cooling your application needs for mission success. With multiple options already available in our COTS products, and our team of engineers to help with modifications or full customization solutions, ESI has your what it takes to keep cool under pressure!

Contact Us Today

As an industry leader, ESI Motion possesses the know-how, experience, and support to help you achieve your mission goals while ensuring optimal performance and longevity for your equipment.

Contact ESI Motion by calling +1.800.823.3235 or email us at sales@esimotion.com. We can help you find the right solution for your space, defense or commercial system needs.

If you’ve got any questions, we’ve probably got them answered here on our FAQ. If you need any technical support, our team is here to help.

Click Here to see more of our solutions.

Check out our products and their capabilities here.