Clutches and brakes are critical to motor driven servo drive systems, helping to transfer torque and stop rotational loads, respectively. However, it’s important to pick the right tool for the job, as each motion control system will require a different kind of clutch, brake, or combination, and that means keeping a few factors in mind.

Clutch, Brake or Combination?

Initially, you’ll need to decide if you need only a clutch, brake or a combination of the two. In general, you’ll want a clutch where you want to disengage a load but leave the motor running, allowing the load to deaccelerate to a stop. You’ll want to use a brake when you need to accurately stop the load and motor at the same time. A combination is best suited when you want to start and stop the load with the motor running.

Mounting

Next, you’ll need to think about how the unit is mounted. For both brakes and clutches, this can be on the motor shaft or base mounted with input from a chain drive, belt drive or a coupling.

Horsepower and Frame

You’ll also need to know the horsepower and frame size of the motor, and for base mounted units, you may also want to know the RPM. Most manufacturers provide selection charts that use the horsepower and speed at the clutch shaft. However, this already assumes the motor is sized correctly. If you know that RPM will be high, you’ll want to talk to the support staff of the manufacturer so you can fully understand how the component operates in terms of heat dissipation.

Coil Voltage

Finally, you’ll want to consider the coil voltage, in most cases, this will be 6V, 24V or 90V. 90V are the most common in North America, while 24V is prevalent in Europe. In either case, you’ll need to consider if you need an AC to DC power converter.

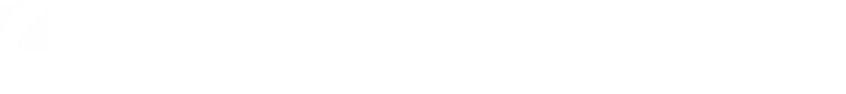

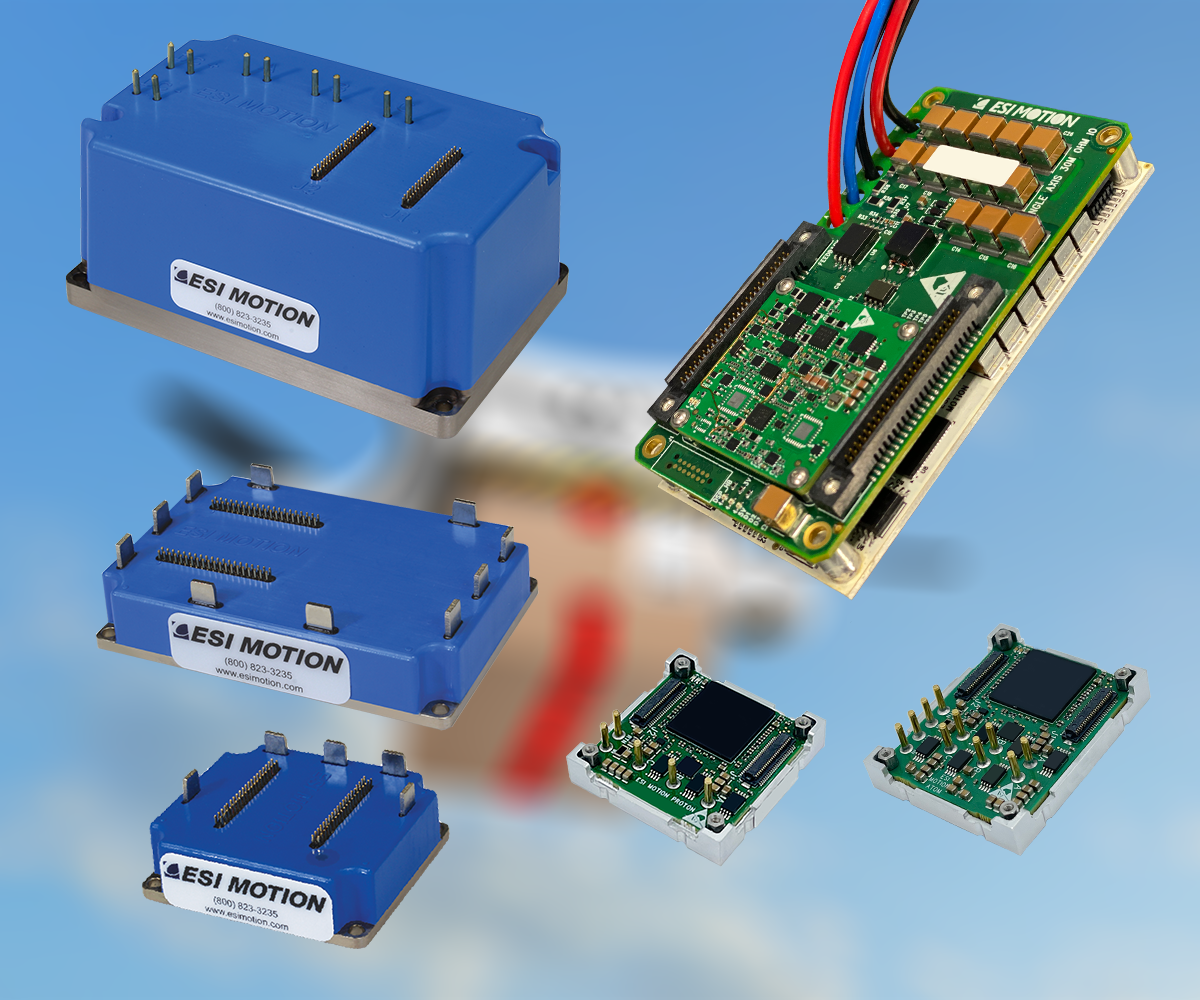

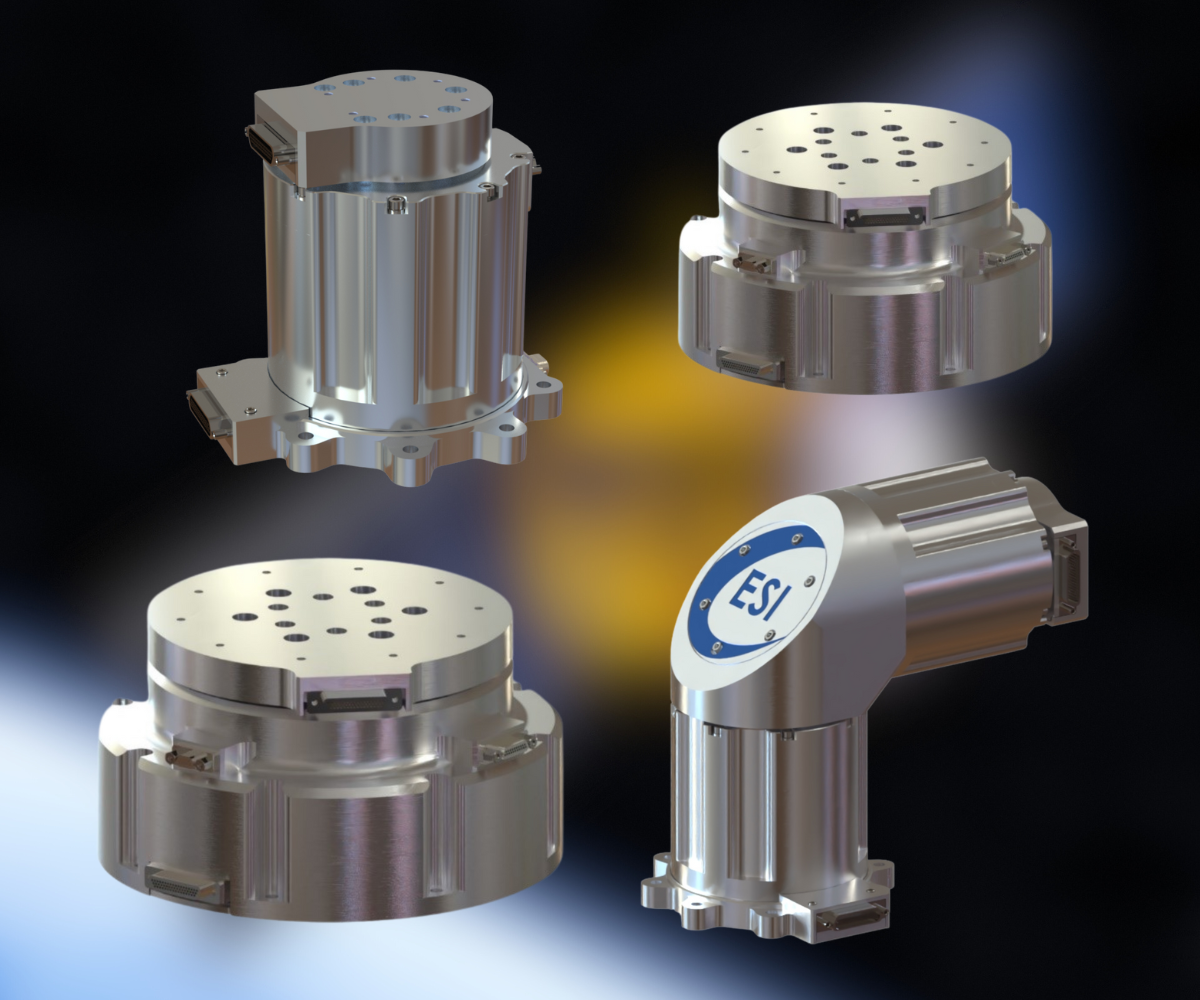

Contact Your High Performance Servo Drive Source

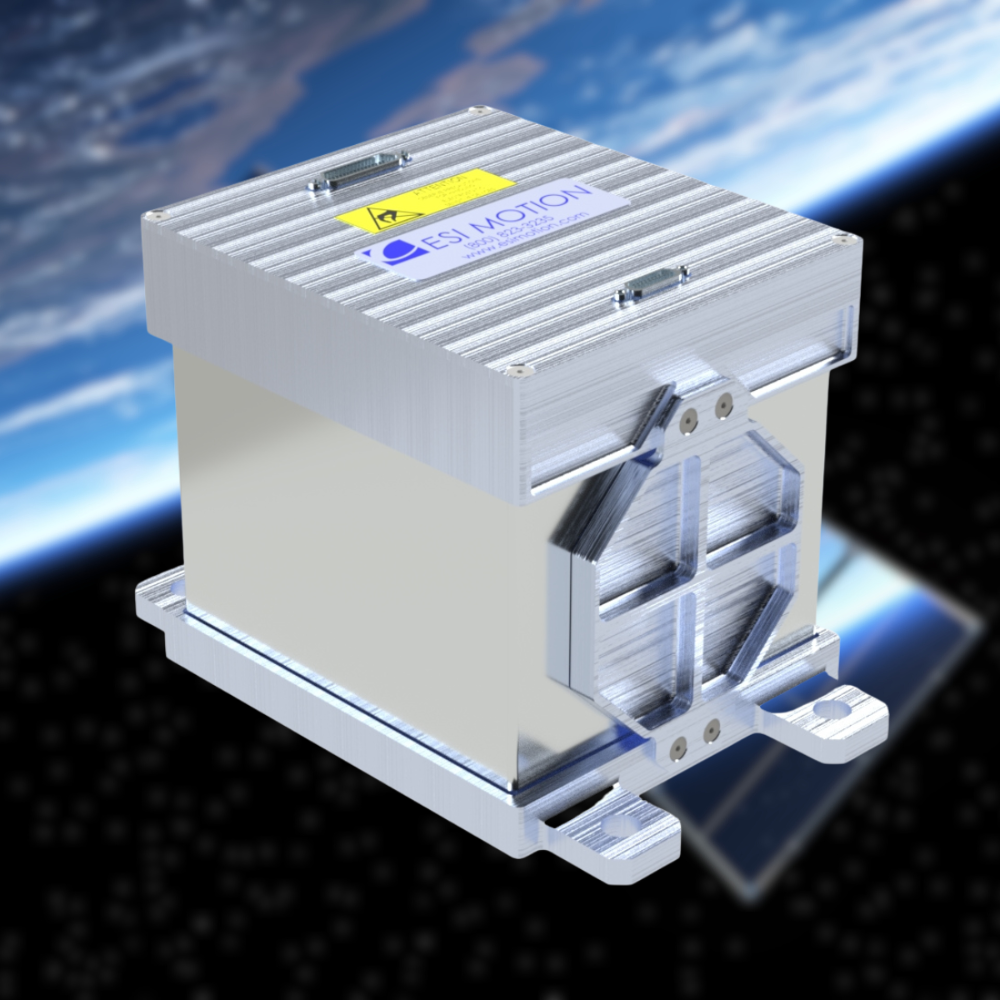

Have more questions about picking the right clutch or brake, or want some of the most powerful servo drives in the world to operate your motors? We’re here to help. Feel free to call us at 800.823.3235, reach out to us, or find out more about our line of extreme environment, high performance products. We can’t wait to hear from you, and we look forward to seeing you back at this blog for more tips and info on optimizing your motion systems.