The face of transportation is going to be disrupted by eVTOLs through a wide range of applications, especially in urban settings. It has been designed to take off and land vertically using electric propulsion, and hence, eVTOLs will have efficient and sustainable solutions to UAM, enabling the quick transportation of passengers and goods around congested cities. Beyond air taxis, the applications of these could span from medical emergencies and cargo delivery to the commute to work and back home-all this heralds a new era of quiet, emission-free, and flexible flight that can reshape how we move within modern cities.

In electric Vertical Take-Off and Landing (eVTOL) applications, servo drives play a critical role in controlling the precise movements and positions of various components such as rotors, control surfaces, and propulsion systems. Here’s a breakdown of their key roles:

1. Precision Control of Propulsion and Flight Systems

Servo drives are used to precisely control the speed and torque of electric motors that drive the rotors or propellers. In an eVTOL, which requires precise vertical and horizontal movement, servo drives provide the fine-tuned control needed for stable hovering, takeoff, and landing. They ensure that the rotors or fans adjust quickly and accurately to maintain balance, stability, and efficiency during flight.

2. Actuation of Control Surfaces

Similar to traditional aircraft, eVTOLs have control surfaces like flaps or rudders that manage direction and stability. Servo drives operate the actuators for these control surfaces, adjusting their position based on flight commands. The accuracy and speed of servo drives help in achieving smooth and responsive maneuvering during transitions from vertical to horizontal flight.

3. Energy Efficiency

eVTOLs rely heavily on electric power, which makes energy efficiency crucial. Servo drives are designed to optimize motor performance by managing current and voltage efficiently. This leads to lower energy consumption during various phases of flight, extending the range of the aircraft and improving overall performance.

4. Fly-by-Wire Systems

Many eVTOL aircraft utilize fly-by-wire technology, where electronic signals (instead of mechanical linkages) are used to control flight surfaces and motors. Servo drives are essential in this system, as they translate the pilot’s commands into precise electrical signals that control actuators and motors. Their ability to operate with low latency is crucial for real-time control and safety in eVTOLs.

5. Redundancy and Safety

Safety is paramount in aviation, and eVTOLs often have redundant systems to ensure reliability in the event of failure. Servo drives can be part of these redundancy systems, ensuring that if one component fails, another can take over. Their robust design and fault detection capabilities can help in implementing safe, fail-operational systems in eVTOLs.

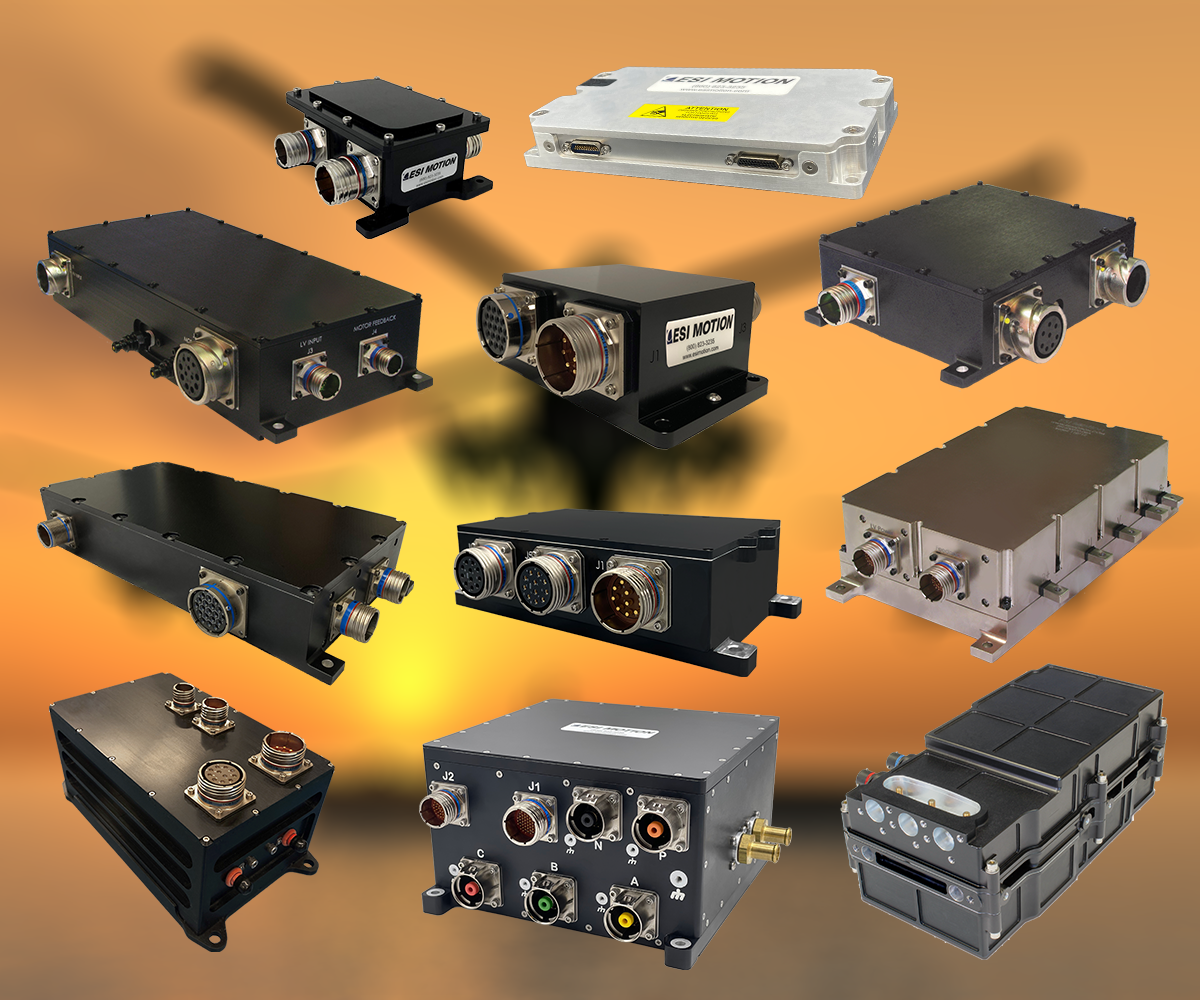

6. Lightweight Design and Compactness

Weight is a critical factor for eVTOLs to maximize efficiency and flight range. Servo drives in eVTOL applications are typically compact and lightweight to minimize the overall weight of the system without compromising on performance. This allows for better energy efficiency and longer operational range, which is especially important in urban air mobility scenarios.

In summary, servo drives are essential for the precise, efficient, and safe operation of eVTOL aircraft. They control propulsion systems, manage actuation of control surfaces, and contribute to the overall energy efficiency and safety of the vehicle. And we have your perfect solution!

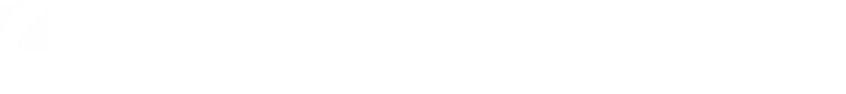

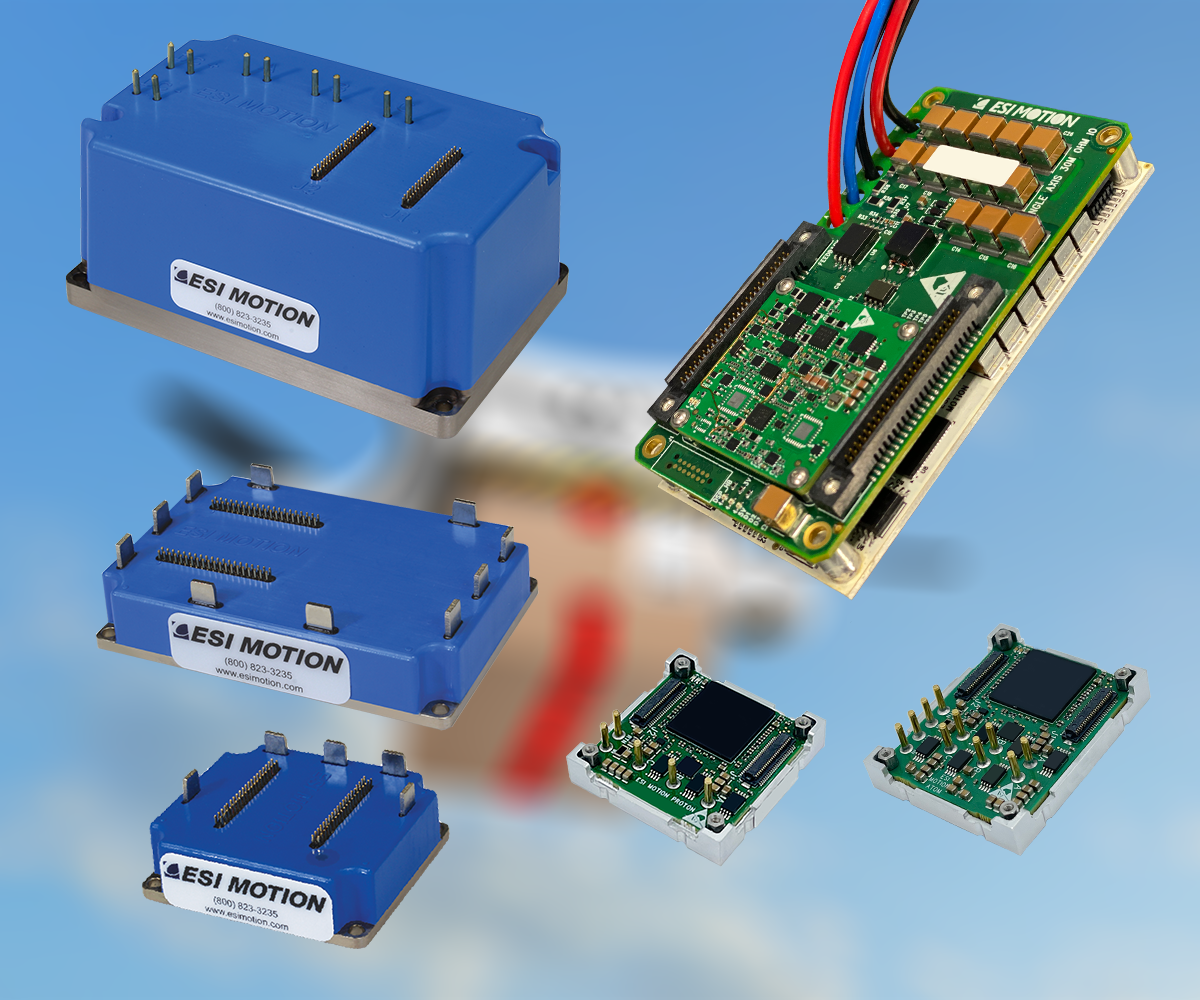

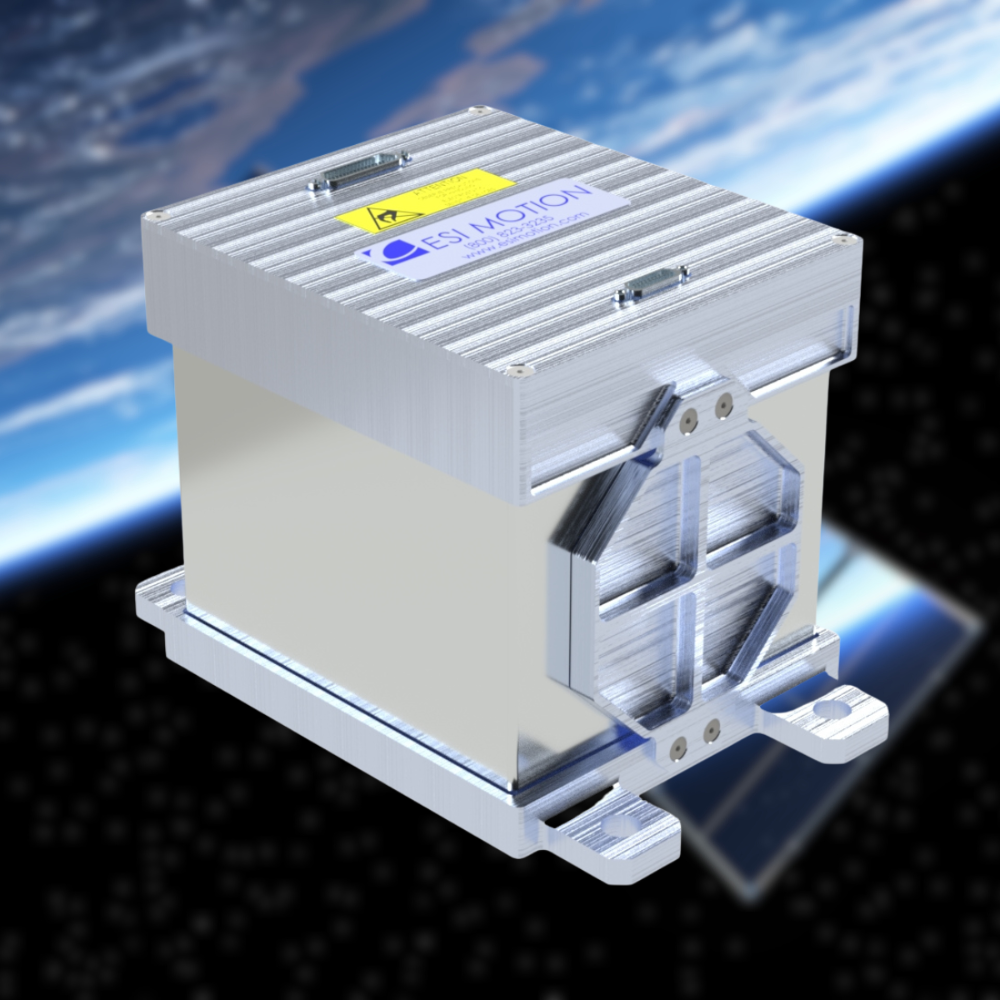

As an industry leader, ESI Motion possesses the know-how, experience, and support to help you achieve your mission goals while ensuring optimal performance and longevity for your equipment. ESI Motion has years of experience providing motion control for a vary of Commercial Applications! Our latest Servo Drive Module, Beetle, is perfect for the applications providing High Power of 300V (600V & 900V models available upon request) without sacrificing size and weight, perfect for these types of applications.

To learn more about Beetle, you can download our Beetle Datasheet. Or Contact ESI Motion by calling +1.800.823.3235 or email us at sales@esimotion.com.

If you’ve got any questions, we’ve probably got them answered here on our FAQ. If you need any technical support, our team is here to help.

Click Here to see more of our solutions.