Feedback in servo drives serves a crucial purpose in ensuring precise control and efficient operation of motor systems. The primary purposes of feedback in servo drives include:

1. Position and Speed Control:

Feedback devices such as encoders, resolvers, or sensors provide real-time information about the position and speed of the motor shaft. This data is essential for the servo drive to accurately control and maintain the desired position or speed of the motor.

2. Closed-Loop Control:

Feedback facilitates closed-loop control systems where the actual performance of the motor is continuously compared to the desired performance. The servo drive adjusts its output based on this feedback, minimizing errors and ensuring the motor operates as intended.

3. Accuracy and Precision:

Feedback enables high precision and accuracy in motion control applications. It allows the servo drive to make fine adjustments to the motor's behavior, resulting in precise positioning and smooth motion.

4. Dynamic Response:

Feedback systems contribute to the dynamic response of servo drives. They enable rapid adjustments to changes in load, speed, or external disturbances, ensuring the motor responds quickly and accurately to varying operating conditions.

5. Error Detection and Correction:

Feedback helps in detecting errors or deviations from the desired motor behavior. The servo drive can use this information to implement corrective actions, maintaining the system's performance within specified tolerances.

6. Enhanced Stability:

Closed-loop feedback systems contribute to the stability of the overall control system. By continuously monitoring and adjusting motor behavior, feedback helps prevent oscillations, overshooting, or other instability issues.

7. Adaptability:

Different types of feedback devices can be used based on the specific requirements of the application. This adaptability allows servo drives to be customized for various industrial processes and machinery.

8. Increased Reliability:

Feedback systems contribute to the overall reliability of servo drives by providing real-time information about the motor's performance. This allows for proactive maintenance and reduces the risk of unexpected failures.

In summary, feedback in servo drives is integral to achieving precise, reliable, and adaptive control of motors in your applications. It ensures that the motor's actual performance aligns closely with the desired performance, optimizing overall system efficiency and accuracy.

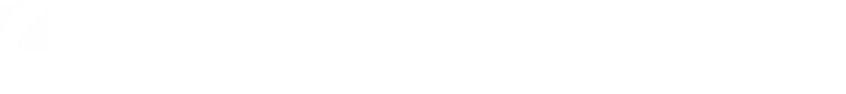

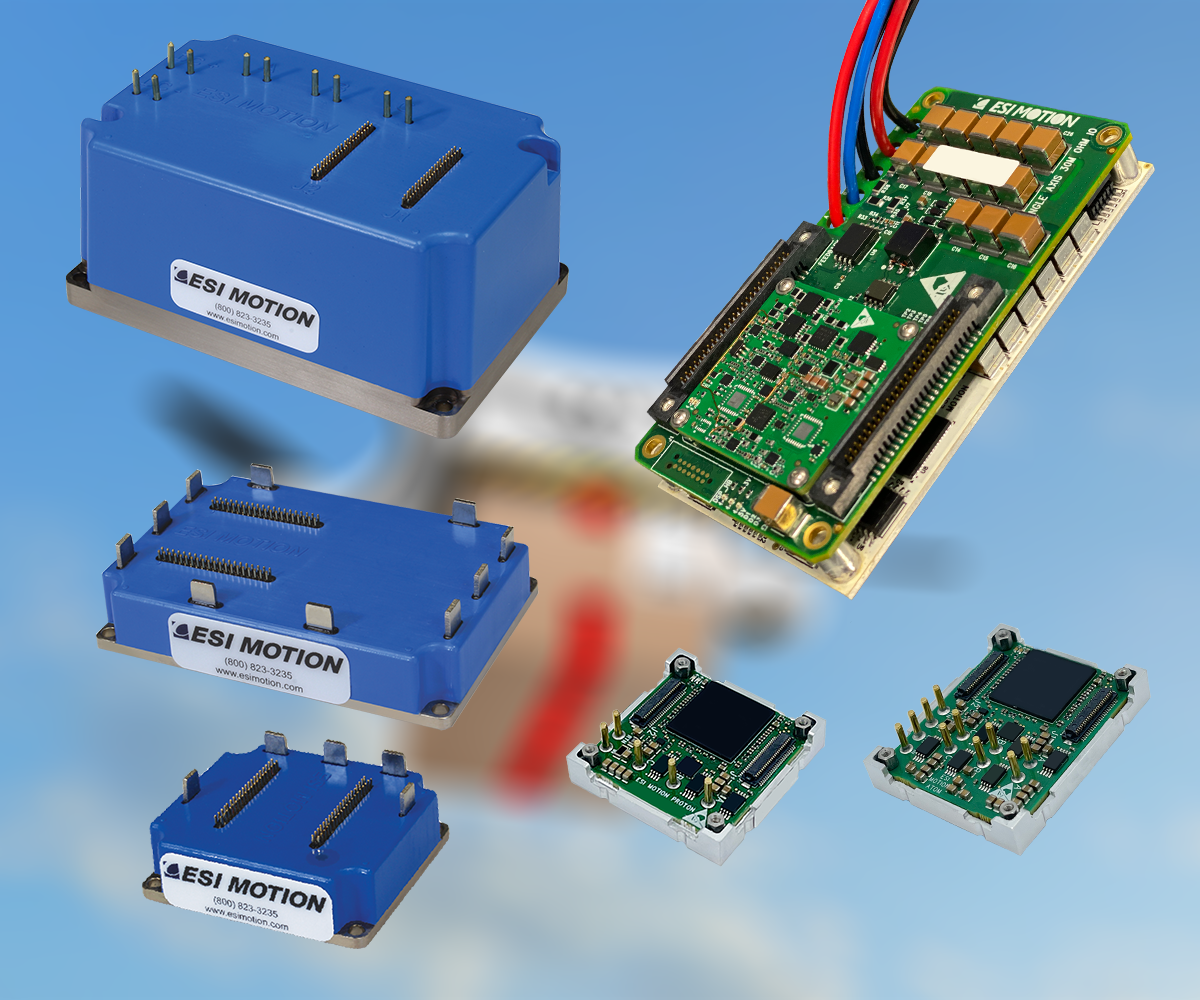

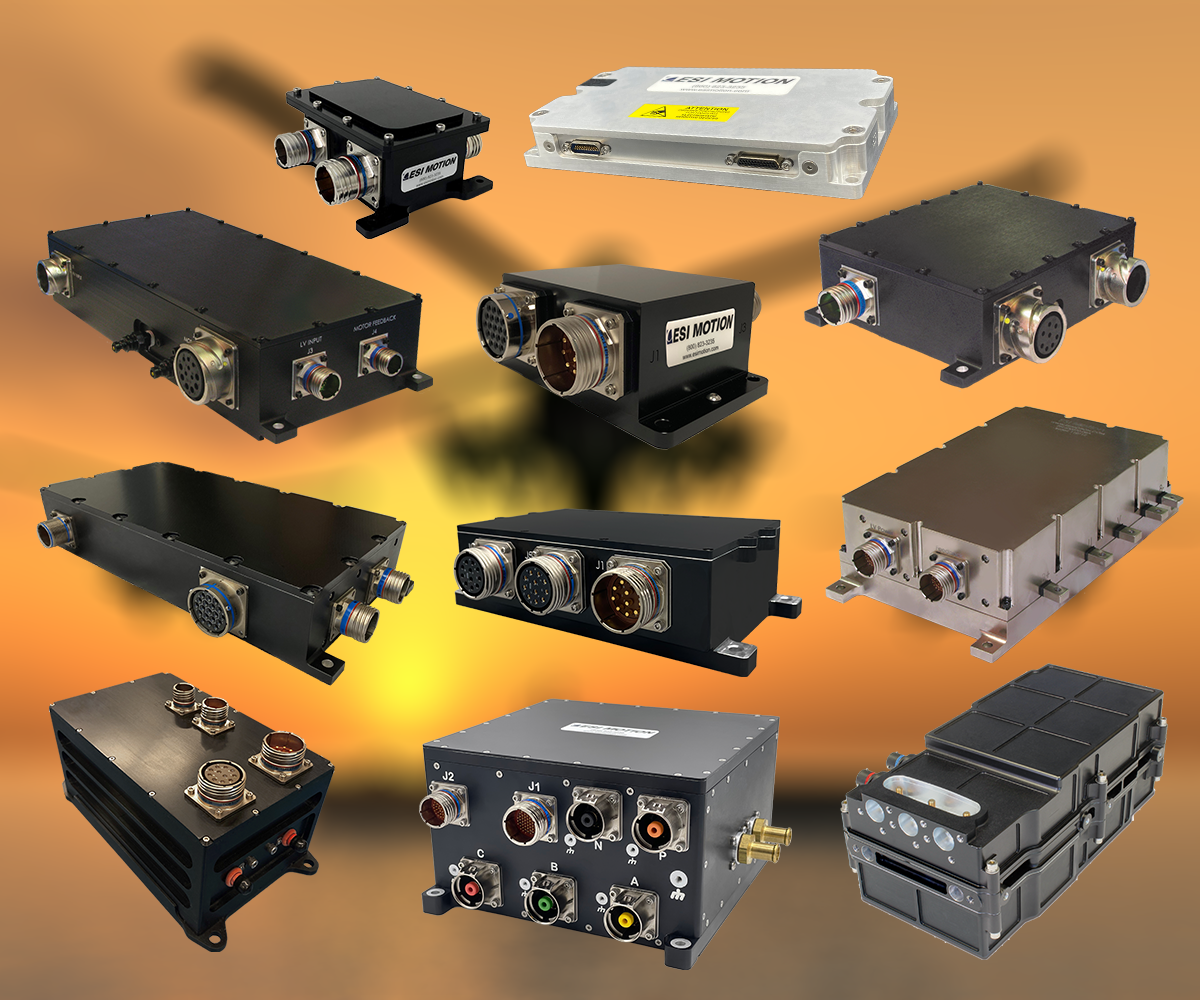

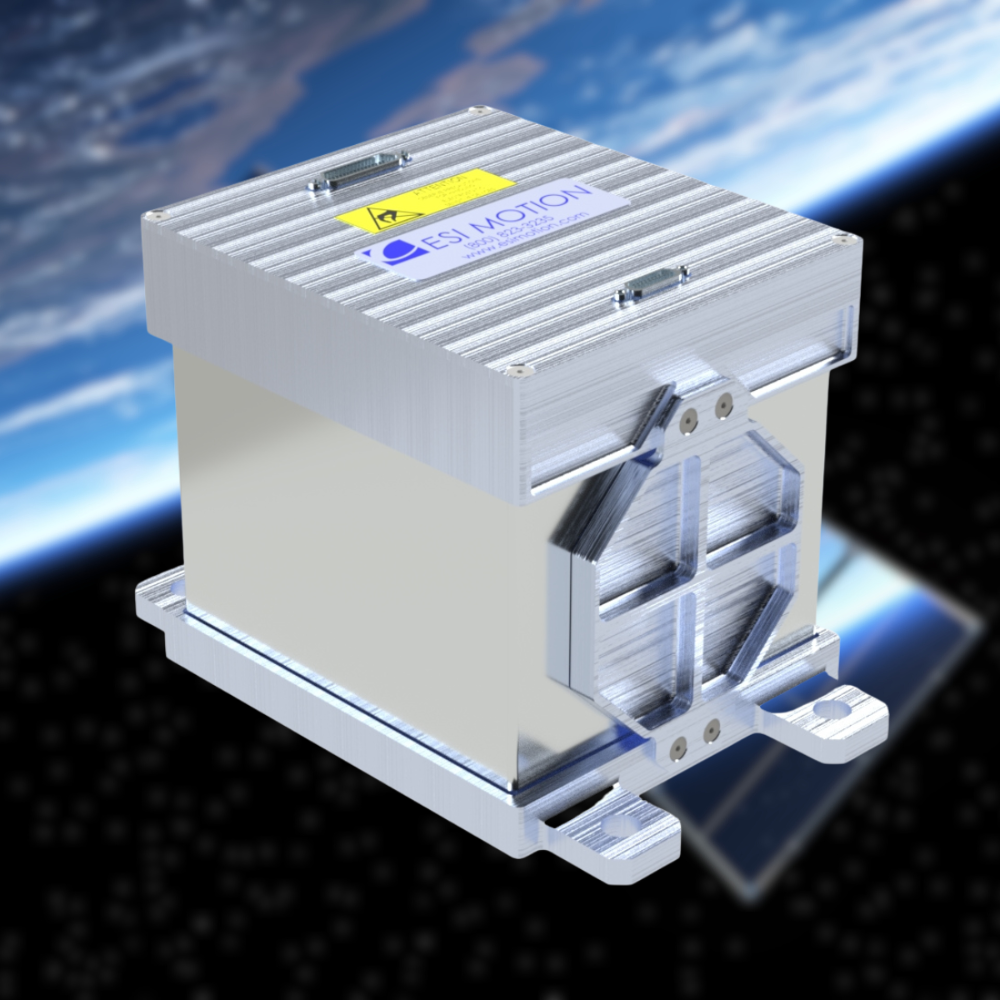

ESI Motion offers multiple forms of feedback (varies by product) in our Commercially Off-The-Shelf products and have years of experience working with different companies to provide modified and custom feedback options to fir your application's motor. We understand that the right feedback is important to a successful, professional environment, process improvement and maintaining the highest team performance; and we know Motion Control Feedback is just as important to success.

Some examples of Feedback Options ESI Motion offer include Resolver, Hall, Sensorless, Quadrature Encoder, BiSS-C (Unidirectional) and our products can include multiple forms available all in the same unit. All options are to provide accurate, timely and precise feedback for all systems in order to continue application success and improve systems to achieve maximum efficiency.

Contact Us Today

As an industry leader, ESI Motion possesses the know-how, experience, and support to help you achieve your mission goals while ensuring optimal performance and longevity for your equipment.

Contact ESI Motion by calling +1.800.823.3235 or email us at sales@esimotion.com. We can help you find the right solution for your application system needs.

If you’ve got any questions, we’ve probably got them answered here on our FAQ. If you need any technical support, our team is here to help.

Click Here to see more of our solutions.

Check out our products and their capabilities here.