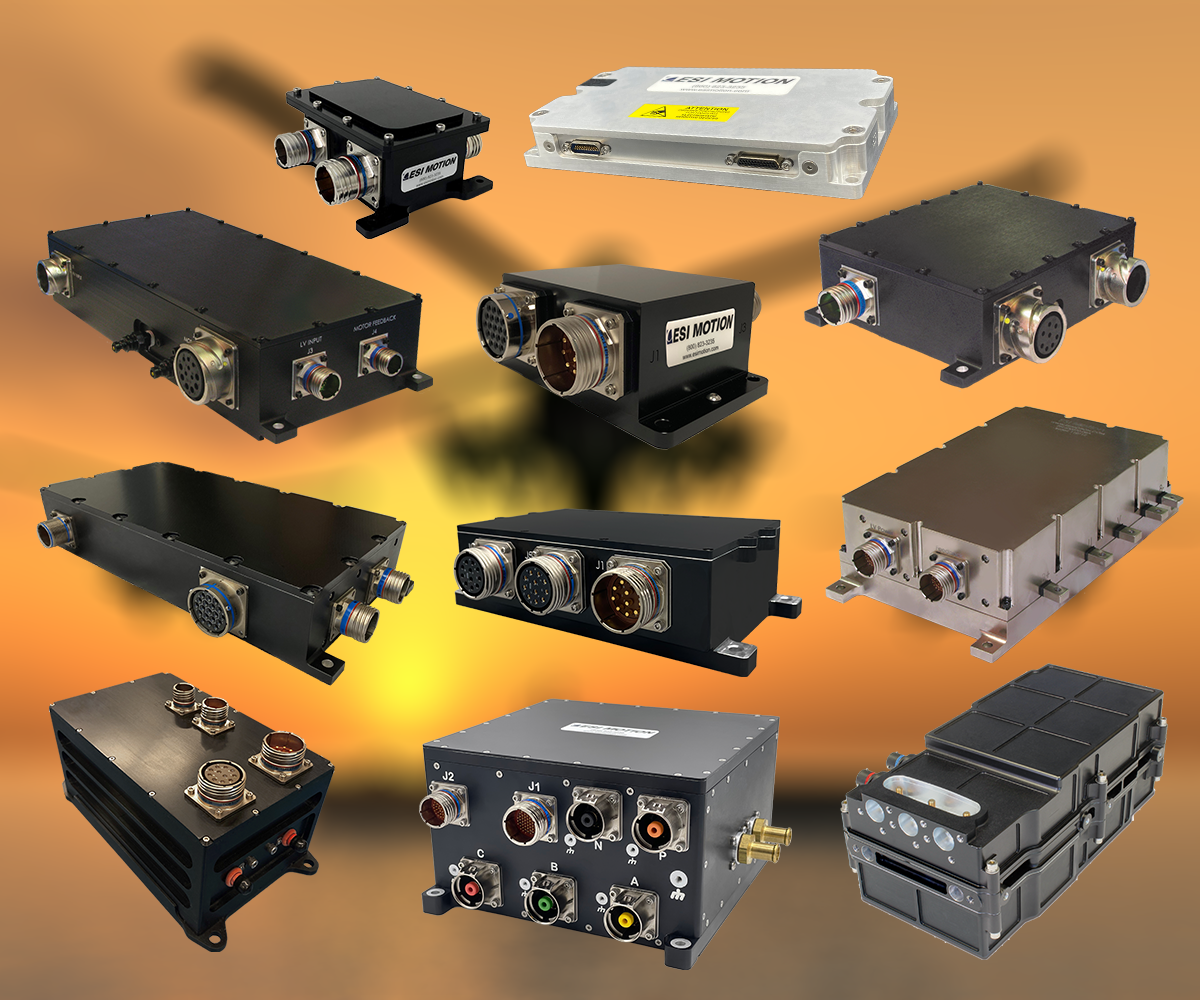

A Servo Drive has to be built to perform sets of multiple tasks or certain coding over and over again while maintaining precision and technique in the harshest environments in order to contribute to mission success. This includes the earthly environments from under the sea to in the atmosphere. In this day in age, those environments now include the frontier of Space and Space Exploration. These Motor Controllers need to be designed, manufactured and tested for Space which includes Low Earth Orbit (LEO), Medium Earth Orbit (MEO) and Geostationary orbit (GEO). The Motor Controller must be a Space-Rated Motor Controller to endure the challenges on the missions.

A space-rated motor controller is essential in space missions for several critical reasons:

Harsh Environmental Conditions: Space is an extremely hostile environment with a vacuum, extreme temperatures (from extremely cold to scorching hot), and intense radiation. A space-rated motor controller is designed to withstand these conditions, ensuring the motor functions reliably without succumbing to extreme temperatures or radiation-induced failures.

Reliability: In space missions, reliability is paramount. Failures can be costly, not only in terms of money but also in terms of mission success and human lives (in the case of crewed missions). Space-rated motor controllers undergo rigorous testing and quality control to ensure they can operate for extended periods without failure.

Longevity: Space missions can last for years or even decades. A motor controller must be designed to function reliably throughout the mission's entire duration, as it may be impossible to repair or replace components once a spacecraft is in space.

Radiation Hardening: Space is filled with various forms of radiation, including solar radiation and cosmic rays. Radiation can damage electronic components, leading to malfunctions or complete failure. Space-rated motor controllers are designed with radiation-hardened components and shielding to mitigate the effects of radiation.

Low Outgassing: Outgassing is the release of gases from materials in a vacuum environment. In space, outgassed materials can deposit on sensitive optical surfaces or contaminate instruments, degrading mission performance. Space-rated motor controllers are constructed from materials that minimize outgassing.

Thermal Management: Space-rated motor controllers must efficiently manage heat generated during operation and dissipate it in the extreme cold of space. Proper thermal design is crucial to prevent overheating and maintain the motor controller's functionality.

Redundancy: To ensure mission success and safety, space systems often incorporate redundancy. Space-rated motor controllers may be designed with redundant components or systems to provide backup in case of primary system failures.

Compatibility: Space-rated motor controllers must be compatible with other spacecraft systems and interfaces. They need to communicate with the spacecraft's central computer, sensors, and other equipment, making compatibility a key requirement.

Mission Specificity: Different space missions have unique requirements for motor controllers, such as specific torque, speed, or precision needs. Space-rated motor controllers can be customized to meet these mission-specific requirements.

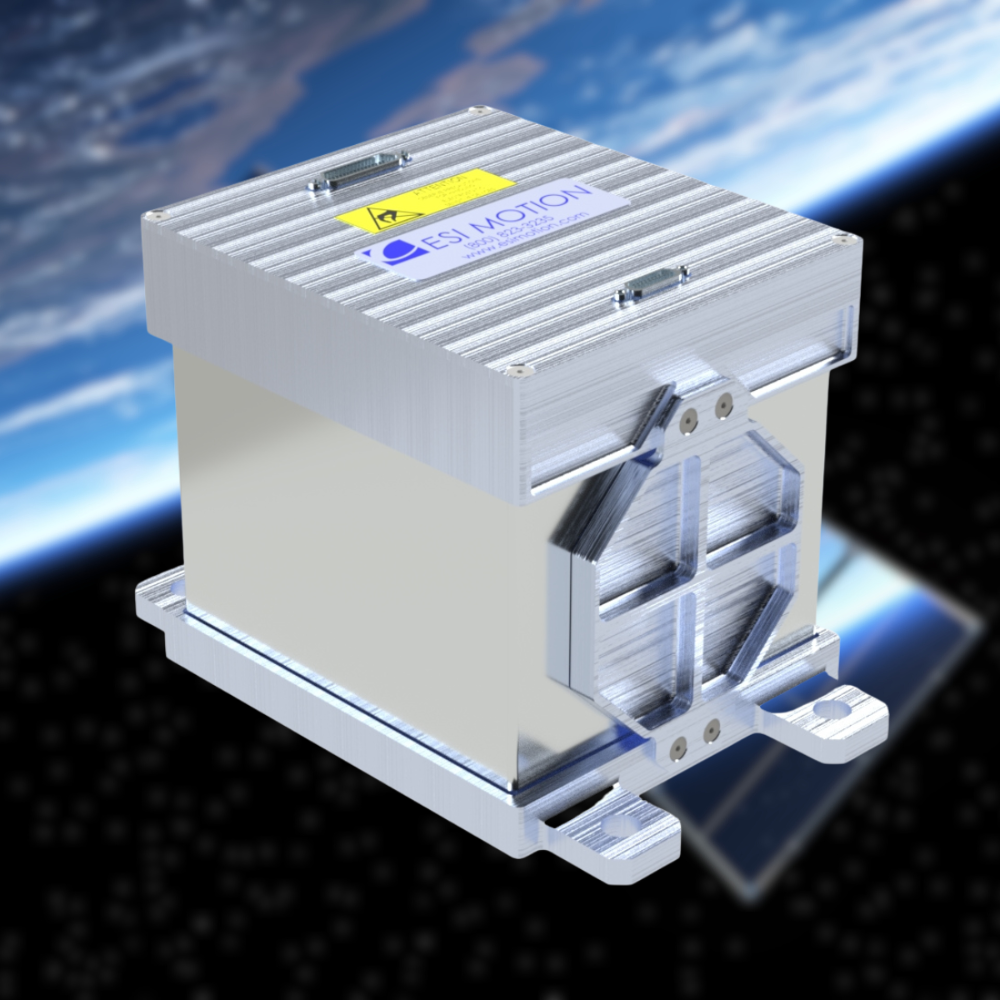

In summary, a space-rated motor controller is essential in space missions to ensure the reliable and safe operation of motors and mechanical systems in the harsh and demanding environment of space. These controllers undergo extensive testing, are designed to withstand extreme conditions, and are critical components in the success of space missions. Both NOVA and SuperNova were designed specifically with these challenges in mind as space exploration continues to grow.

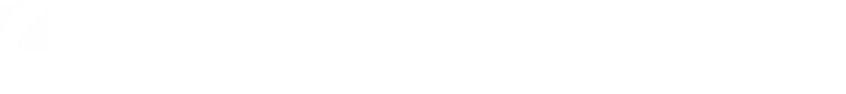

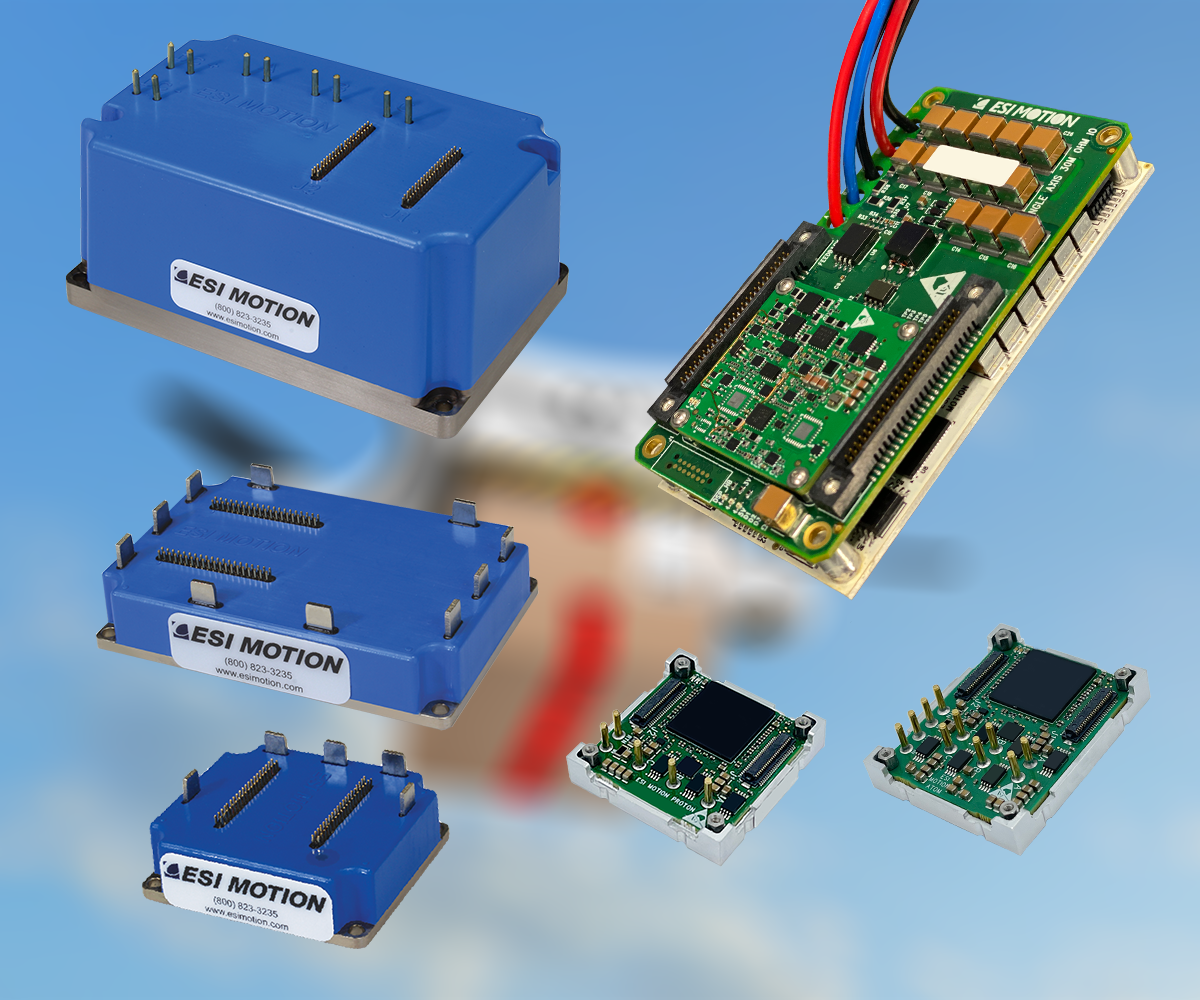

ESI Motion engineers have partnered with numerous laboratories, research institutions and other agencies to provide motor control solutions that precisely suit each client’s distinctive requirements. In addition to providing a wide range of off-the-shelf servo drives and modules, we deliver advanced solutions to satisfy mission critical applications. This makes our team uniquely qualified to Support the most advanced technical requirements for LEO and GEO applications.

If you want to learn more or have any questions, Contact Us Here!